To

manage the configuration of projects for the creation of integrated logistics

systems certain management processes should be performed, among which control

processes are important. Changing components of the project environment have a

significant impact on the configuration of projects for creating integrated

logistics systems. These components act as limiting factors in the

justification of the parameters of logistics systems. At the same time, there

is a need to use tools for managing the configuration of integrated projects

for creating logistics systems, which involves taking into account their

specific project environment (Pavlikha et al., 2019).

To do this, it is

necessary to substantiate the scientific and methodological principles that

underlie the implementation of control processes for the configuration of

integrated projects for the creation of logistics systems.

1.

LITERATURE REVIEW

It

is known that the effectiveness of any project, including projects to create

integrated logistics systems, is largely due to the availability and use of

management tools that take into account the characteristics of these projects

and their specific design environment (Kolodiichuk, 2016).

Several scientific works are devoted to solving

managerial problems of project configuration management and the impact of the

project environment on it (Ratushnyi et al., 2019) as well as

international standards.

Well-known papers Sumets (2017) concern the analysis of

the possibility of using the configuration management tools of projects of

different applied branches. The models and methods proposed there involve the

use of traditional approaches, that do not take into account the features of

integrated projects to create logistics systems.

Certain

scientific works Bashynsky (2019) are devoted to

the solution of management problems in projects for the creation of integrated

systems, which are based on their forecasting and control processes. Their main

advantages are taking into account the specifics of the subject area. However, it is impossible to use them while managing the

configuration of integrated projects for logistics systems creation, as they do not

take into account the specifics of the subject area and the impact of

components of the project environment on management processes and configuration

of relevant projects (Ratushny, Bashynsky & Ptashnyk, 2019).

When implementing integrated projects for the creation of

logistics systems, their configuration should be controlled. This control is

carried out during the life cycle of projects. According to current

international standards Bashynsky (2019), all configuration objects must be

monitored to ensure that the configuration complies with documented

requirements, indicators, and characteristics (Boyarchuk, et

al., 2019).

However, this document provides general approaches to

project configuration control. These approaches do not make it possible to

control the configuration components of integrated projects for the creation of

logistics systems.

They do not provide any control over documented

requirements, indicators and characteristics. So, there is a need for the

development of scientific and methodological foundations for controlling the

configuration of integrated projects for the creation of logistics systems.

The developed scientific and methodological foundations

eliminate the shortcomings of the existing ones. They are based on the theory

of project configuration management and system-factor principles (Hulida, et

al., 2019).

The formulated management problem is solved in the

article, which confirms its scientific and practical value.

The

research aims to

substantiate the scientific and methodological foundations for controlling the

configuration of integrated projects for creating logistics systems, taking

into account the changing components of their project environment. To achieve

this aim, it is necessary to solve the following

tasks:

·

to propose a scientific

and methodological basis for controlling the configuration of integrated

projects for the creation of logistics systems, taking into account the

changing components of their project environment;

·

substantiate a configuration control model

for integrated projects of

logistics systems creation.

2.

MATERIALS AND METHODS

Configuration control of integrated logistics systems

projects is the process of applying administrative and technical procedures at

each stage of the life cycle of these projects to ensure compliance with the

configuration with documented requirements, indicators, and characteristics (Boyarchuk, et

al., 2019).

This process involves managing the changes that are made to the configuration

objects after justifying the basic configuration of the integrated logistics

projects (Vann, 1996).

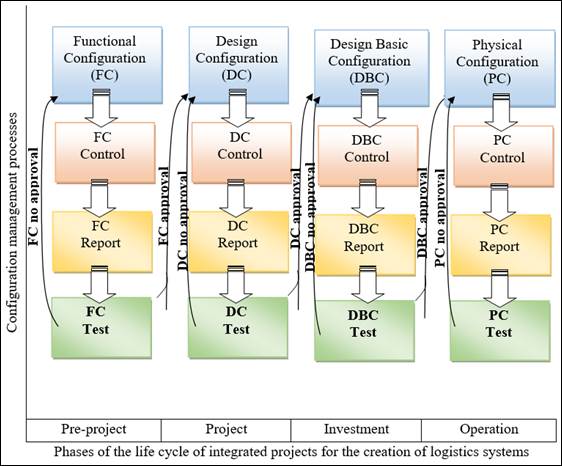

There are four types of configurations within integrated

projects for the creation of logistics systems, namely: functional

configuration (FC); design configuration (DC); design basic configuration (DBC);

physical configuration (PC). Each of them characterizes the completion of the

stages of the life cycle of individual projects that are integrated Figure 1 (Òryhuba et al., (2020).

After

identifying the configuration of projects, their changes should be monitored.

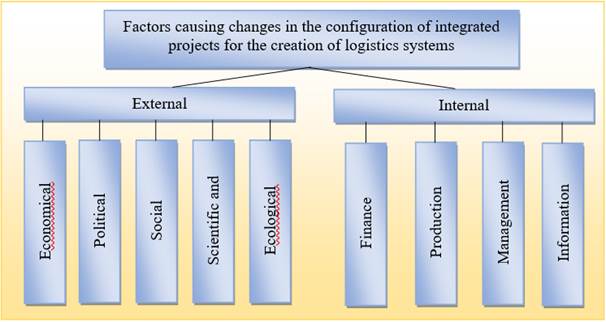

Changes in the configuration of integrated projects for the creation of

logistics systems are due to several factors. All factors that cause changes in

the configuration of these projects can be conditionally divided into two

groups: external and internal Figure 2 (Tryhuba et al., 2021).

Figure 1: Scheme of configuration management of integrated projects for

the creation of logistics systems

Source: compiled by the

authors

Figure 2: Factors causing changes in the configuration of integrated

projects for the creation of logistics systems

Source: compiled by the

authors

External

factors include the following groups:

·

economic (Åc),

·

political (Pl),

·

social (Sc),

·

scientific and technical (St),

·

ecological (Ål).

Economic

factors include the level and rate of inflation, fluctuations in the exchange

rate of the national currency against the currencies of other countries,

taxation, conditions for obtaining a loan and the bank interest rate, the level

of prices for dairy products. For example, an increase in energy prices causes

an increase in prices for storage and all types of products obtained, and

especially those in the logistics of which most of the energy costs are spent (Rudynets

et al., 2019).

The

political group of factors characterizes the stability both in the state and in

the territory of implementation of integrated projects for the creation of

logistics systems. The influence of political factors on the configuration of a

particular project is particularly noticeable in an unstable socio-economic and

political environment. The unstable political situation causes an outflow of

capital from projects that require significant long-term investment and affect

relations with foreign partners.

A

social group of factors is formed within a particular region and reflects the

views, values, and preferences of people, which affects the sale of finished

products obtained from logistics systems. Besides, the deliberate disregard of

the requirements of the current legislation for the implementation of

integrated projects for the creation of logistics systems leads to deviations

in the indicators of the documented configuration (Syrotiuk et al., 2020).

Scientific and technical factors influencing changes in

the configuration of integrated projects for creating logistics systems include

discoveries, inventions that make it possible to reduce the cost of procurement

of raw materials, transportation of raw materials, storage of raw materials,

production of finished products, and storage of finished products without

changing its quality. This indicates that the control center of integrated

projects for the creation of logistics systems should analyze the possible

impact of scientific and technological progress on the effectiveness of these

projects, and accordingly on changes in their configuration (Òryhuba et al., 2019).

The

ecological group of factors includes more than normalized emissions of

pollutants and toxic substances into the environment; the size of possible

irreversible negative consequences, etc.

External factors influencing changes in the configuration

of integrated projects for the creation of logistics systems are characterized

by a high level of variability, uncertainty, and unpredictability.

The internal factors that cause changes in the

configuration of individual integrated projects for the creation of logistics

systems include finance (Fn), production (Pr), management (Mn), and information

(If). The financial insolvency of a particular project requires changes in the

documents regarding its configuration. These changes involve replacing the

proposed configuration objects with cheaper ones or changing their number,

which will make the project cheaper. Regarding production factors, they should

include:

1) variability of the

characteristics of the design environment (territorial location of logistics

facilities and volumes of raw materials and finished products for which

logistics systems are designed, etc.);

2) changes in the range of

products, which causes changes in the quality requirements of raw materials,

and, accordingly, changes in the time functional indicators of the objects of

the configuration of logistics systems.

The management group of factors includes the objectivity

of the identification of the configuration of a particular project to create a

logistics system and the reliability of individual decisions regarding its

changes. Besides, the management group of factors is characterized by the forms

of organization of activities for the implementation of projects and the

distribution of responsibilities between project participants, which

significantly affect the functional performance of the configuration objects (Sokulskyi

et al., 2020).

The effectiveness of decision-making on changes in the

configuration of integrated projects for the creation of logistics systems is

largely influenced by the information group of factors, which is characterized

by the timeliness and completeness of the information obtained about the

project environment.

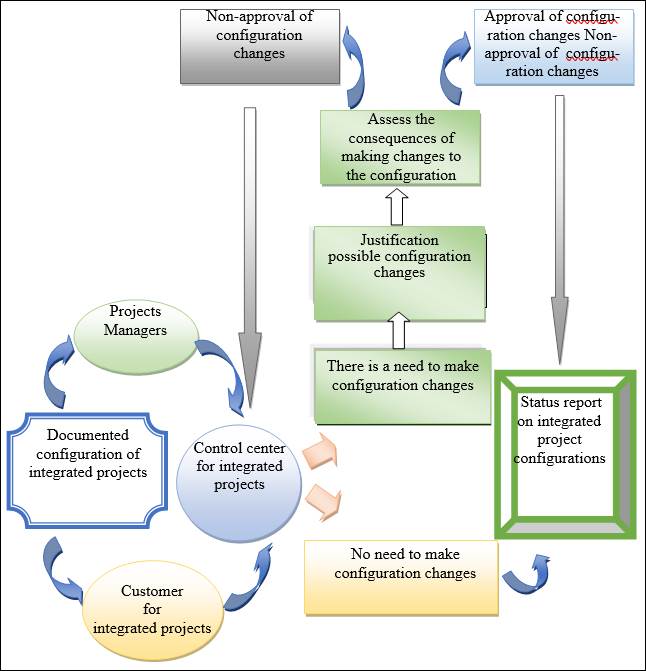

We propose a model for monitoring changes in the

configuration of integrated projects for the creation of logistics systems (Figure

3).

Figure 3: Model of the execution of the configuration control process of

integrated projects for the creation of logistics systems

Source: compiled by the

authors

It assumes that the management process is carried out

both by the customer or investor of these projects and by the team that

implements these projects. They analyze documented configuration objects and

their performance, changes in the design environment, and the factors that

cause these changes (Tryhuba et al., 2018).

The results of the analysis are submitted to the meeting

of the management center of integrated projects for the creation of logistics

systems. The Center for Management of Integrated Projects for the Creation of

Logistics Systems approves decisions on the expediency of the need to make

changes to the configuration of these projects, or their absence.

If there is a need for changes in the configuration of

integrated projects for the creation of logistics systems, then a justification

of possible options for its changes and the consequences of them is carried

out. If there is such a configuration option for integrated projects for the

creation of logistics systems, in which it is possible to significantly

increase the efficiency of their implementation, the changes made are approved

and a report on the configuration status of these projects is carried out. If

the changes made to the configuration of integrated projects for the creation

of logistics systems are not approved, the control center reconsiders the need

to make changes to it (Tryhuba et al., 2020).

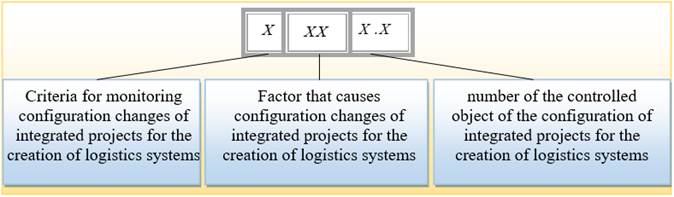

The

following criteria are used to control changes in the configuration of integrated

projects for the creation of logistics systems:

·

functionality

(F);

·

reliability (R);

·

efficiency

(E);

·

mobility (M).

Functionality (F) is the ability of a configuration

object to meet current requirements for the functions assigned to it. Reliability

(R) is the ability of a configuration object to keep the values of all its

parameters within a set time interval.

Efficiency (E) - is assessed by the indicators of the

configuration objects of a particular project to create logistics systems,

which reflect the ratio of benefits (values) to the cost of their

implementation.

Mobility (M) is the ability of the object of the

configuration of a particular project to create logistics systems to move

territorially within the internal environment of the project. Each of the

configuration objects is assigned a code depending on the evaluation criterion

and the factor that determines the configuration changes of integrated projects

for the creation of logistics systems (Figure 4).

Figure: 4: Coding of configuration objects of integrated projects for

the creation of logistics systems to perform the process of their control

Source: compiled by the

authors

After assigning

evaluation codes to configuration objects regarding the influence of design environment

factors on changes in the configuration of integrated projects for the creation

of logistics systems, evaluation tables are developed, which contain assigned

evaluation codes of configuration objects of individual projects, methods for

evaluating changes and their quantitative value Table 1 (Òryhuba et al., 2020).

Table 1: Example of assessment of the impact of internal

factors of integrated projects for the creation of logistics systems on changes

in the configuration object No. 4.1 (specialized tank truck for transportation

of perishable goods)

|

No.

|

Assigned code

|

Evaluation method

|

Evaluation

indicator , points , points

|

Significance

coefficient,

|

|

1

|

FFn4.1

|

Expert

|

6

|

0,022

|

|

2

|

FFn4.1

|

Expert

|

3

|

0,03

|

|

3

|

ÅFn4.1

|

Expert

|

1

|

0,035

|

|

4

|

ÌFn4.1

|

Expert

|

30

|

0,02

|

|

5

|

FPr4.1

|

Simulation

|

2

|

0,01

|

|

6

|

RPr4.1

|

Expert

|

4

|

0,01

|

|

7

|

ÅPr4.1

|

Simulation and

calculation

|

1

|

0,025

|

|

8

|

ÌPr4.1

|

Expert

|

6

|

0,02

|

|

9

|

FÎr4.1

|

Expert

|

5

|

0,06

|

|

10

|

RÎr4.1

|

Expert

|

3

|

0,15

|

|

11

|

ÅÎr4.1

|

Simulation and calculation

|

15

|

0,031

|

|

12

|

ÌÎr4.1

|

Expert

|

6

|

0,045

|

|

13

|

FMn4.1

|

Expert

|

2

|

0,06

|

|

14

|

RMn4.1

|

Expert

|

3

|

0,01

|

|

15

|

ÅMn4.1

|

Expert

|

1

|

0,036

|

|

16

|

ÌMn4.1

|

Expert

|

1

|

0,02

|

|

17

|

FIf4.1

|

Expert

|

2

|

0,3

|

|

18

|

RIf4.1

|

Expert

|

4

|

0,01

|

|

19

|

ÅIf4.1

|

Expert

|

3

|

0,026

|

|

20

|

ÌIf4.1

|

Expert

|

2

|

0,08

|

For each of the assigned codes (evaluation criteria and

factors that determine the configuration changes) of the configuration objects

of integrated projects for the creation of logistics systems, the significance

coefficient is substantiated.  .

.

The numerical value of the coefficient  is in the range from 0 to 1 and it characterizes the significance of

each of the

is in the range from 0 to 1 and it characterizes the significance of

each of the  factors on the -th object of the configuration of integrated

projects for the creation of logistics systems. Quantitative assessment of the

impact of design environment factors on changes in the configuration of

integrated projects for the creation of logistics systems is carried out on a

100-point scale.

factors on the -th object of the configuration of integrated

projects for the creation of logistics systems. Quantitative assessment of the

impact of design environment factors on changes in the configuration of

integrated projects for the creation of logistics systems is carried out on a

100-point scale.

The next step is to determine the generalized assessment

characteristics of the impact of design environment factors on changes in the

configuration of integrated projects for the creation of logistics systems. These

include absolute  and relative

and relative  indicators of the impact of design

environment factors on changes

indicators of the impact of design

environment factors on changes  object of configuration of

integrated projects for logistics systems creation.

object of configuration of

integrated projects for logistics systems creation.

The absolute indicator  of the influence of design environment factors on changes in the

configuration objects of integrated projects for the creation of logistics

systems is determined by the formula

of the influence of design environment factors on changes in the

configuration objects of integrated projects for the creation of logistics

systems is determined by the formula

, (1)

, (1)

where  – an estimated indicator of the influence of ³ factor of the project environment

according to the

– an estimated indicator of the influence of ³ factor of the project environment

according to the  criterion on changing the configuration objects of integrated projects

for the creation of logistics systems, points;

criterion on changing the configuration objects of integrated projects

for the creation of logistics systems, points;  – the coefficient of the significance of the influence of ³ factor of the project

environment according to

– the coefficient of the significance of the influence of ³ factor of the project

environment according to criterion on changing the

configuration objects of integrated projects for the creation of logistics

systems.

criterion on changing the

configuration objects of integrated projects for the creation of logistics

systems.

The relative indicator  of the influence of design environment factors on changes in the

configuration objects of integrated projects for the creation of logistics

systems is determined by the formula

of the influence of design environment factors on changes in the

configuration objects of integrated projects for the creation of logistics

systems is determined by the formula , (2)

, (2)

where  – baseline impact score of ³ factor of the project

environment due to

– baseline impact score of ³ factor of the project

environment due to  criterion for changes in the

configuration objects of integrated projects for the creation of logistics

systems, points.

criterion for changes in the

configuration objects of integrated projects for the creation of logistics

systems, points.

Based on the configuration control of integrated projects

for the creation of logistics systems, a report on the effectiveness of the

configuration is carried out and its verification is performed. If, as a result

of the identified check, it is established that the configuration does not meet

the requirements for it, then it should be returned to the process of its

identification. Identification is performed based on well-known algorithms,

methods, and models that are presented in scientific papers (ANSI/EIA649,

1998; Bashynsky, 2019;

Islam & Mandal, 2017).

Therefore, the proposed scientific and methodological

principles of configuration control of integrated projects for the creation of

logistics systems indicate the possibility of using them during the implementation

of these projects to ensure compliance of the documented configuration with

requirements, indicators, and characteristics taking into account the changing

design environment.

3.

CONCLUSIONS

The analysis of the current scientific and methodological

principles of project management shows that they cannot be used to control the

configuration of integrated projects to create logistics systems, as they

provide common approaches to controlling project configuration and do not take

into account many factors of the project environment.

It is substantiated that changes in the configuration of

integrated projects of logistics systems are caused by two groups of factors,

which are evaluated by four criteria based on the definition of two generalized

evaluation characteristics of the impact of design environment factors on

configuration changes of these projects.

The proposed scientific and methodological principles of

control of the configuration of integrated projects of logistics systems,

taking into account the changing components of their design environment are

based on project management theory and system-factor principles and fully take

into account the implementation of integrated projects of logistics systems and

can be used to control their configuration.

Further research on the configuration control of

integrated projects for the creation of logistics systems should be conducted

to establish the quantitative value of the planned targets of the generalized

assessment of the impact of design environment factors on changes in the

configuration of these projects.

REFERENCES

ANSI/EIA649

(1998).

National Consensus Standard for Configuration Management. Government Electronics & Information

Technology Assoc.,

20041998.

Bashynsky, O. (2019). Coordination of dairy workshops projects on

the community territory and their project environment. In: 14-th International Scientific and Technical

Conference on Computer Sciences and Information Technologies. Lviv Polytechnic National

University, 17–20 September. Lviv, pp. 51–54.

Boyarchuk, V., Tryhuba, I., Boyarchuk, V., &

Ftoma, O. (2019). Evaluation of risk value of investors of projects

for the creation of crop protection of family dairy farms. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis, 67(5), 1357–1367.

Hulida, E., Pasnak, I., Koval, O., & Òryhuba, A. (2019). Determination

of the Critical Time of Fire in the Building and Ensure Successful Evacuation

of People. Periodica Polytechnica

Civil Engineering, 63(1), 308-316.

Islam, S., & Mandal, W. A. (2017). A fuzzy inventory

model (EOQ model) with unit production cost, time depended holding cost,

without shortages under a space constraint: a fuzzy parametric geometric

programming (FPGP) approach. Independent Journal of Management &

Production, 8(2), 299-318. DOI: 10.14807/ijmp.v8i2.535.

Kolodiichuk, V. (2016).

Management of logistic systems agrarian enterprises. Agricultural and Resource Economics, 2(4),

106–117, available at: https://are-journal.com/are/article/view/69.

Pavlikha, N., Rudynets, M., Grabovets, V., Skalyga, M., Tsymbaliuk, I., Khomiuk, N., & Fedorchuk-Moroz, V.

(2019). Studying the influence of production

conditions on the content of operations in logistic systems of milk collection. Eastern-European Journal of Enterprise

Technologies: Control processes,

99(3/3), 50–63.

Practice

Standard for Project Configuration Management (2007). Project Management Institute. Four

Campus Boulevard, Newton Square, PA 19073-3299, USA.

Ratushny,

R., Bashynsky, O., & Shcherbachenko, O. (2018). Identification of firefighting system

configuration of rural settlements, Fire

and Environmental Safety Engineering. MATEC Web Conf. 247, pp. 1–8.

Ratushny, R., Bashynsky, O., & Ptashnyk, V. (2019). Development

and usage of a computer model of evaluating the scenarios of projects for the creation

of fire fighting systems of rural communities. In: XI-th International Scientific and Practical Conference on Electronics

and Information Technologies.

Ivan Franko National

University of Lviv, 16–18 September. Lviv, pp. 34–39.

Ratushnyi, R., Khmel, P., Martyn, E., & Prydatko, O.

(2019). Substantiating the effectiveness of

projects for the construction of dual systems of fire suppression. Eastern-European Journal of Enterprise

Technologies: Control processes, 100(4/3), 46–53.

Rudynets, M., Pavlikha, N., Kytsyuk, I., Korneliuk, O., Fedorchuk-Moroz, V., &

Seleznov, D. (2019). Establishing patterns of change in the

indicators of using milk processing shops at a community territory. Eastern-European Journal of Enterprise

Technologies: Control processes,

102(3/6), 57–65.

Sokulskyi, O., Hilevska, K., Chumakevych, V.,

Ptashnyk, V., & Sachenko, A. (2020). The

Internet of Things Solutions in the Investigation of Urban Passenger Traffic

and Passenger Service Quality. In: IEEE

European Technology and Engineering Management Summit (E-TEMS). Dortmund, Germany, 5-7 March 2020. pp. 1–10.

Sumets, A. (2017). Agro-logistics: necessity and

opportunity for the development. Agricultural and Resource Economics, 3(3), 119–129. Available

at: https://are-journal.com/are/article/view/124.

Syrotiuk, V., Syrotiuk, S., Ptashnyk, V., Baranovych,

S., Gielzecki, J., & Jakubowski, T. (2020). A hybrid system with intelligent control

for the processes of resource and energy supply of a greenhouse complex with

application of energy renewable sources. Przegląd elektrotechniczny, 96(7), 149-152.

Tryhuba A., Zachko, O., Grabovets, V., Berladyn, O., Pavlova, I., & Rudynets, M. (2018). Examining

the effect of production conditions at territorial logistic systems of milk

harvesting on the parameters of a fleet of specialized road tanks. Eastern-European Journal of Enterprise Technologies, 5(3), 59-70.

Tryhuba, A., Boyarchuk, V., Tryhuba, I., Ftoma, O., Francik, S., & Rudynets, M. (2020). Method

and software of planning of the substantial risks in the projects of production

of raw material for biofuel. In: International Workshop IT Project Management. Ukrainian

Project Management Association “UKRNET” & Lviv Polytechnic National

University, 18–20 February. Slavsko, 116–129.

Vann, J. M. (1996). TWRS Configuration management program

plan. In: United States, DOI: http://dx.doi.org/10.2172/662064.

Òryhuba, A., Bashynskyi, O., Medvediev, Y., Slobodian, S.,

& Skorobogatov, D. (2019).

Justification of models of changing project environment for harvesting grain,

oilseed and legume crops. Independent

Journal of Management & Production, 10(7), 658-672.

Òryhuba, A., Hridin, O., Slavina, N., Mushenyk, I., &

Dobrovolska, E. (2020). Managerial decisions in logistic systems of

milk provision on variable production conditions. Independent Journal of Management & Production, 11(8), 783-800.

Òryhuba, A., Òryhuba, ²., Mushenyk, ²., Pashñhenko, Î., & Likhter, Ì. (2020). Computer model of

resource demand planning for dairy farms. Independent Journal of Management & Production, 11(9),

658-672.

PECULIARITIES

OF IMPLEMENTATION OF CONFIGURATION CONTROL PROCESSES OF INTEGRATED AND

INNOVATIVE PROJECTS OF LOGISTICS SYSTEM CREATION

PECULIARITIES

OF IMPLEMENTATION OF CONFIGURATION CONTROL PROCESSES OF INTEGRATED AND

INNOVATIVE PROJECTS OF LOGISTICS SYSTEM CREATION