MODELING

OF MICROBIOLOGICAL AND BIOCHEMICAL PROCESSES UNDER THE CONDITIONS OF STEAM

CONTACT STERILIZATION IN CONTAINERS OF TURKEY MEAT PATE

MODELING

OF MICROBIOLOGICAL AND BIOCHEMICAL PROCESSES UNDER THE CONDITIONS OF STEAM

CONTACT STERILIZATION IN CONTAINERS OF TURKEY MEAT PATE

Tetiana Prylipko

State Agrarian and EngIneering University in Podilya, Ukraine

E-mail: tprilipko59@gmail.com

Volodymyr Kostash

State Agrarian and EngIneering University in Podilya, Ukraine

E-mail: kostashv@ukr.net

Tetiana Koval

State Agrarian and EngIneering University in Podilya, Ukraine

E-mail: kovaltanya@i.ua

Alina Shuliar

Zhytomyr National Agroecological University, Ukraine

E-mail: alyonashulyar7@gmail.com

Volodymyr Tkachuk

Zhytomyr National Agroecological University, Ukraine

E-mail: volodymyr.tkachuk@lnu.edu.ua

Alona Shuliar

Zhytomyr National Agroecological University, Ukraine

E-mail: alyonashulyar7@gmail.com

Submission: 9/7/2020

Revision: 9/21/2020

Accept: 03/24/2021

ABSTRACT

The article proposes modes of sterilization of meat pate from turkey meat,

which was determined by the method in which the actual lethality Ff relative to

the microflora should be equal to or exceed the required lethality of the

sterilization process Fn (Ff ≥ Fn) canned turkey pate. The results of the

study of the dependence of the kinetics of biochemical reactions on the

thermal, chemical and mechanical sensitivity of the processed product, on pressure,

temperature and chemical potential are

presented. One of the effective ways to intensify the heat transfer process is

the contact heating of the product by means of steam supply, which has a

technological effect on the processed products. When comparing the results of

the simulated results with experimental data, it is established that the

solution of the problem of calculating the temperature field of the product on

a computer gives quite satisfactory results between the calculated and

experimental data. It is established

that as a modification for the processed products it is necessary to solve

thermohydromechanical equations with the corresponding initial and boundary

conditions in addition to the transfer equation for each scalar quantity.

Keywords: Pressure; Temperature; Parameters; Stea; Contact heating; Production; Sterilization; Microflora; Packaging; Diffusion; Physico-chemical

Parameters

1.

INTRODUCTION

Targeted combination of prescription

ingredients provides a food composition with a given chemical composition. This approach forms the basis of the use of

raw materials, the main advantage which is the potential for mutual enrichment

of ingredients included in the recipe for one or more essential factors with in

order to ensure the fullest compliance created compositions of the formula

of balanced or adequate nutrition Antipova (2015), Buttriss, (2006) and Tsurkan, Gurich and Polevoda (2014).

An important task of the meat

canning industry is to increase production and improve product quality by optimizing

technological processes, identifying and using hidden reserves, saving raw

materials and energy resources. Meat

pate is a source of essential human proteins, calcium, iron and some vitamins,

the lack of which leads to a delay in physical development, reduced

immunity. Insufficient meat in the human

diet slows down the metabolism. Canned

meat, namely pâtés, are products made from meat, offal and other

raw materials in hermetically sealed containers and pasteurized or sterilized

to kill microorganisms and Make Them Stable During Storage (Prylipko,

Bukalova & Lyasota, 2019;

Yakubchak, 2014).

To date, the range of meat products

still lacks scientifically sound recipes for canned meat products in the form

of general-purpose pâtés that would meet the standards of healthy

eating. The production of combined

products, which can include canned pâtés, can be considered as

part of the man-made technological sphere (Cherevko & Poperechny, 2014; Vynnykova, 2006; Zhang et al., 2015).

It is known that the nutritional

value of meat products depends on the content of biologically important

components, the change of which in the process of processing has a decisive

influence on the quality of finished products in relation to the enzymes of the

gastrointestinal tract, ability to digest and meet certain physiological

needs. In a balanced diet, turkey pate

has no substitutes. Their nutritional

value is characterized by high caloric content and digestibility (Belk, George & Tatum 2012; Bohirov, Shcherbakov & Bakunova, 2013).

The scientific substantiation of

rational modes of sterilization of pâtés should be reduced not

only to the study of the possibility of reducing the sterilizing effect in the

production of industrial sterile products, but also to establish the

dependences of objective criteria of quality and nutritional value. Particular attention should be paid to the

study of structural changes in proteins and lipids in canned pâtés

depending on the composition and modes of heat treatment (Tsurkan, Gurich & Polevoda, 2014; Kaletnik & Yanovich, 2017).

2.

LITERATURE REVIEW

The kinetics of biochemical

reactions to varying degrees depends on the thermal, chemical and mechanical

sensitivity of the processed product, pressure, temperature and chemical

potential. The pressure propagates in

the fluid according to the Pascal principle in all directions, passing for

small adiabatic changes of pressure with the speed of sound. For this reason, it can be assumed that the

pressure occurs almost instantly throughout the chamber.

From this assumption follows the

available in the literature not tested enough in real conditions conclusion

that the influence of pressure in comparison with thermal processes has the

advantage that it can affect rapidly and uniformly the entire processed

substance, regardless of shape, size and composition. However, the possibility

of physical and thermal inhomogeneity is ignored, which is explained by the

fact that in the phase of pressure increase due to the change in volume, the

temperature of the treated medium increases (Voronenko, 2008; Prilipko & Kutsyi, 2013; Ibatullin, Zhukorsky & Bashchenko, 2017).

The creation of high-performance

heat exchange equipment that meets the current level of development of industry

and technology requires significant intensification of heat transfer

processes. One of the effective ways,

both in terms of intensification of the heat transfer process and energy

savings, is the contact heating of the product by means of steam, which has a

technological impact on the processed products (Palamarchuk, Polvado & Kutsyi, 2017).

Heat transfer during steam contact

heating of products is a complex phenomenon associated with the simultaneous

transfer of heat and mass of matter. The

amount of transferred mass is determined by the amount of condensed steam, and

the transferred heat (provided saturated steam) - the heat of vaporization (Kaletnik & Yanovich, 2017).

When steam-contact heating takes

into account a significant number of determinants, with the greatest importance

are both thermophysical properties of the heating steam and physico-chemical

properties of the product. Taking into

account all the factors influencing the heat transfer process during steam

contact heating is very difficult not only theoretically but also

experimentally (Bogatko, Bukalova &

Lyasota, 2019; Terziev, 2012).

The main parameter in the process of

thermal sterilization of food products, including by means of steam contact

heating, is the temperature of the product, which is the main factor for

establishing the sterilization modes of canned food. Therefore, one of the main tasks in the study

of the sterilization process with this method of heating is to determine the

temperature field of the product or to detect the dynamics of temperature

change at different points of the product depending on the parameters of

heating steam, its supply conditions and physical properties of processed raw

materials (Prylipko, Koval & Kostash, 2020; Lyasota &

Bakhur, 2020).

The

purpose of the article - calculation of non-stationary

temperature field in a container heated from the outer surface from a heat

source of a given intensity, taking into account convection in the radial

direction.

1.

DATA AND METHODOLOGY

In the study and development of new technological

solutions for canned meat pate that meets modern market requirements and the

principles of healthy eating, the rationale for the optimal sterilization of

canned turkey pate was based on analytical, statistical and comparative

research methods.

To achieve this goal it was

necessary to solve the following tasks:

·

to optimize

the mode design parameters of the vertical autoclave of periodic action

B6-KA2-B-2;

·

to carry out

mathematical modeling of recipes of meat pate taking into account new types of

raw materials and balance of the main components on conformity to requirements

of a healthy food and to develop a compounding and the technological scheme of

production of pate from turkey meat;

·

to carry out

rotatable central-compositional planning of multifactorial experiment on the

basis of search experiments;

The

article proposes modes of sterilization of meat pate from turkey meat, which

were determined by the method in which the actual lethality Ff relative to the

microflora should be equal to or exceed the required lethality of the

sterilization process Fn (Ff ≥ Fn).

Research methods:

biochemical (influence of enzyme preparations on collagen-containing raw

materials), physicochemical (changes in the chemical composition of turkey meat

under the action of heat loads and during storage), statistical (biometric

processing of research materials (Zhuravskaya, Alekhina & Otryashenkova, 2015). Software: MathCad,

MicrosoftExel, Compass - 3DV12 were used for theoretical research. To verify

the adequacy of the obtained experimental results, we used the method of

mathematical statistics using the program Statistics 6.0.

2.

RESULTS AND DISCUSSIONS

To formally determine the increase in temperature caused by the increase in

pressure, we first used the conservation equation from which we derived

equation (1.) relative to the total heat capacity H.

(1)

(1)

- fluid velocity vector,

- fluid velocity vector,

– weight force vector,

– weight force vector,

– liquid density, kg / m3;

– liquid density, kg / m3;

– pressure, Pa;

– pressure, Pa;

- hour, s.;

- hour, s.;

– tensor of viscous stresses.

– tensor of viscous stresses.

He then used the equation

for a specific heat capacity h

(2)

(2)

F - dissipation function,

and using

the thermodynamic ratio

(3)

(3)

– coefficient of thermal expansion,

– coefficient of thermal expansion,

we obtained the equation

of thermal energy,

(4)

(4)

For example, water at room

temperature shows an increase in temperature from 2.5 K to 3 K when compressed

to 100 MPa. In the case of a similar

experiment with edible oils, the temperature rise can reach 10 K and above (Prilipko & Kuts,2013).

It is believed that the movement of

the liquid is necessarily present during the treatment of the liquid substance

by pressure. To show this

mathematically, we assumed that the density increases with increasing pressure

and decreases with increasing temperature, which is justified for most foods

and similar substances in the environment.

The appearance of the running field in a fluid that is initially at

rest, during compression, we showed using the equation of mass balance.

(6)

(6)

During the compression phase, the

density increases with increasing pressure.

Therefore, the first term of equation (6) becomes nonzero. Since the left side must be zero, the fluid velocity must take non-zero

values. Therefore, increasing the

pressure enhances the movement of the fluid.

Temperature gradients play an important role in the deviation of flow

behavior from the hydrostatic state. We

traced this conclusion using the basic equations of hydrostatics:

must take non-zero

values. Therefore, increasing the

pressure enhances the movement of the fluid.

Temperature gradients play an important role in the deviation of flow

behavior from the hydrostatic state. We

traced this conclusion using the basic equations of hydrostatics:

(7)

(7)

(8)

(8)

(9)

(9)

In equations (7-9) x, y and z are

Cartesian coordinates. Without losing

sight of the general idea, we assumed that the vector of gravity points in a

negative direction. Further

transformation of equation (8) in relation and equation (9) in relation gave

the following result:

(10)

(10)

Therefore, the right-hand side of

equation (10) and the density derivative with  respect

to the relation must be constant and equal to zero (Tsurkan, Gurich & Polevoda, 2014)

respect

to the relation must be constant and equal to zero (Tsurkan, Gurich & Polevoda, 2014)

(11)

(11)

However, this condition, as follows

from hydrostatics, cannot be maintained.

While the density is a function of temperature, and the latter is

transmitted in a direction different from the direction of the vector of

gravity, equation (11) is violated. As a

result, the flow of steam at a rate other than zero must occur, which leads to

convective transfer of high temperature and suspended solids.

The presence of thermal

inhomogeneity in the product and the subsequent inhomogeneity of the process

make it necessary to predict thermal inhomogeneity, including for the

application of countermeasures.

The results of a numerical

experiment to calculate the temperature field along the radius of a cylindrical

container depending on the parameters of the heating steam and the product are

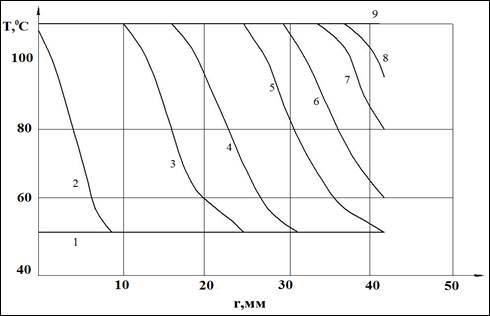

presented in Figure 1.

Figure 1:

Curves of temperature field changes in the process of steam contact heating of

the product in a cylindrical container with external heat supply at the

temperature of the heating steam Òï =

100 °Ñ :1 – t = 0; 2 – t = 1; 3 – t = 20; 4 – t = 40; 5 – t = 80; 6 – t = 120;

7 – t = 160; 8 – t = 180; 9 – t = 200

In Figure 1 curves of changes in the temperature field of

the product during steam heating of the product from the initial temperature Tn

= 50 ° C to the final temperature Tk = 100 ° C condensing steam with a

temperature Tp = 100 ° C, with a steam flow rate of 0.001 kg / s The ambient temperature is taken Ts = 20 ° C,

and the heat transfer coefficient on the outer surface of the cylinder = 10 W /

(m K). As can be seen from Fig. 1 at the initial time (1.5-3 s) the

temperature in the Central layer almost instantly increases to the condensation

temperature of the vapor. The

temperature in the peripheral layers of the product does not change.

Upon further heating, mainly due to

the emerging radial convective flows, as well as thermal conductivity, the heat

flux gradually reaches the peripheral layers over time t = 260 s. As a result, a uniform temperature field is

established over the entire radius. To

determine the influence of the parameters of the heating steam on the

distribution of the temperature field of the product, we performed calculations

at different temperatures of the heating steam. (Palamarchuk. Polyevoda & Kutsyi,

2017)

In fig. In Figure 2

shows the curves of changes in the temperature field at the temperature of the

heating steam Tp = 110 ° C. As can be

seen, the increase in temperature contributes to the intensification of the

heat transfer process. However, this

leads to a sharp temperature difference between the central and peripheral

regions.

Comparison of the results of the simulated

results with experimental data allows us to conclude that the solution of the

problem of calculating the temperature field of the product on a computer gives

quite satisfactory results between the calculated and experimental data.

Figure 2: Curves

of temperature field changes in the process of steam contact heating of the

product in a cylindrical container with external heat supply at the temperature

of the heating steam Tp = 110 ° C: 1 - t = 0; 2 - t = 1; 3 - t = 20; 4 - t =

40; 5 - t = 80; 6 - t = 120; 7 - t = 160; 8 - t = 180; 9 - t = 200

The transfer of molecular (index m)

and cellular (index z) systems occurs by means of mechanisms induced by forced

and natural convection. Based on small

length ranges ( m for proteins and

m for proteins and  m for microorganisms) they are in mechanical and thermal equilibrium. Characteristic internal time scales of pulse

transfer into water as a dispersion medium

m for microorganisms) they are in mechanical and thermal equilibrium. Characteristic internal time scales of pulse

transfer into water as a dispersion medium  s and

s and  s give instructions on

mechanical equilibrium.

s give instructions on

mechanical equilibrium.

Similarly characterize the internal time scales  s and

s and  s energy transfer to water. These estimates require further consideration

near the phase transition boundaries.

There is a significant change in the state of "reaction time to

thermohydrodynamic effects", because they create velocity fields, fields

induced by friction of normal stresses and tangential stresses, as well as

pressure and temperature fields.

s energy transfer to water. These estimates require further consideration

near the phase transition boundaries.

There is a significant change in the state of "reaction time to

thermohydrodynamic effects", because they create velocity fields, fields

induced by friction of normal stresses and tangential stresses, as well as

pressure and temperature fields.

The above dimensions of the internal

time scales of dispersed molecular and cellular systems differ significantly

from the typical duration of the process τïðîö* processing.

So, Deborah's number  takes an infinitesimal value. This

dimensionless index expresses the local equilibrium, i.e. the presence of a

"congruent thermohydrodynamic state" of the continuous phase and

dispersed molecular and cellular systems at any time under the influence of

high pressure at given spatial coordinates, which greatly facilitates modeling,

as it allows us to reflect the technological impact on molecular and cellular reactions as

general scalar quantities Θ*. In dimensionless form for the relation

takes an infinitesimal value. This

dimensionless index expresses the local equilibrium, i.e. the presence of a

"congruent thermohydrodynamic state" of the continuous phase and

dispersed molecular and cellular systems at any time under the influence of

high pressure at given spatial coordinates, which greatly facilitates modeling,

as it allows us to reflect the technological impact on molecular and cellular reactions as

general scalar quantities Θ*. In dimensionless form for the relation  we received the corresponding transfer model:

we received the corresponding transfer model:

(12)

(12)

The

left side of the model equation completely coincides with the equation of

conservation of mass. For the molecular

biocomponent, equation (12) expresses the induced changes that are associated

with diffusion, as well as with a qualitative change (activation or

deactivation) of biocomponents.

Diffusion effects are based on the existence of inhomogeneous scalar

fields Θ.

Parameter DΘ in the first term of the right side of

equation (12) is given for the diffusion constant of the molecular or cellular

process. The magnitude of the diffusion

obviously depends on the inverse of the product of the Reynolds test Re0

and Schmidt's criterion

Schmidt's criterion evaluates

the ratio of diffusion momentum to scalar transfer  . he next effect associated with positive or

negative "production"

. he next effect associated with positive or

negative "production"  , expresses a dimensionless initial term

, expresses a dimensionless initial term . The

value of the Damköller criterion

. The

value of the Damköller criterion  sets the

intensity of the source

sets the

intensity of the source  . It describes the relationship

between the convection time scale and the molecular reaction time scale. For example, in the reaction of the nth order

with concentration

. It describes the relationship

between the convection time scale and the molecular reaction time scale. For example, in the reaction of the nth order

with concentration  source intensity

source intensity  Damköller's

criterion is

Damköller's

criterion is  .

.

One of the main ideas of equation (12) is that molecules - if the required

values of the thermodynamic variable pressure and temperature prevail - react

accordingly.

Therefore, cellular responses can be

modeled similarly (Cherevko

& Poperechny, 2014) Pressure-induced suppression of

microorganisms as a scalar quantity depends on the intensity of the source of

vital suppression (for example, the pressure in combination with the

barosensitivity of the corresponding microorganisms), diffusion transfer of

destroyed microorganisms based on pure Brownian motion and convective transfer

based on forced coercion. Introducing the initial term into equation (12),

we proceeded from the hypothesis that in addition to the local mechanical and

thermal equilibrium between the dispersed and continuous phases, there is local

homogeneity.

Specifically, this means that the

reactions both in the considered place of the processed product and in its

immediate spatial environment take place depending on the same local

thermohydrodynamic state. Thus, in

places with a spatially very small distance between the reactions that take

place, there are no mutual influences, no restrictions and slowdowns. Since these interactions are completely

unavoidable, we considered it rational to despise the interactions if the

average distance s* between two

molecules or microorganisms takes significantly more value than their

characteristic length scales im ³ iz. Checking the probability of this

requires calculating the size of the next criterion, the Knudsen number Kn,

which is used in gas dynamics for comparative reasoning.

To

achieve the goal of our research, we adapt the definition of Knudsen's number as  . As a result, we assumed that

local homogeneity approximately exists at low concentrations of dispersed

systems, ie for larger values

. As a result, we assumed that

local homogeneity approximately exists at low concentrations of dispersed

systems, ie for larger values  . Checking the probability of

local homogeneity, ie that no relationships occur between adjacent spatial

zones, is also of great importance for scaling.

This is due to the fact that the measurement of the kinetic data of the

reaction takes place in very small cells operating under pressure, in which the

effect of thermohydromechanical distributions is relatively small. Not only local but also, to a certain extent,

global homogeneity should prevail approximately here. In contrast, the distributions of

thermohydromechanical fields that inevitably occur in large chambers can affect

the reaction rate in a way other than that expressed by equation (12).

. Checking the probability of

local homogeneity, ie that no relationships occur between adjacent spatial

zones, is also of great importance for scaling.

This is due to the fact that the measurement of the kinetic data of the

reaction takes place in very small cells operating under pressure, in which the

effect of thermohydromechanical distributions is relatively small. Not only local but also, to a certain extent,

global homogeneity should prevail approximately here. In contrast, the distributions of

thermohydromechanical fields that inevitably occur in large chambers can affect

the reaction rate in a way other than that expressed by equation (12).

Given these conditions, we concluded

that the transfer of mass, momentum, energy, and scalars has a strong effect on

the interaction, however, an exact similarity cannot be achieved. This works, in particular, if the goal is to

set specific results of technological influence, such as inactivation of

cellular and molecular systems, but it is a significant difficulty not only for

scaling, but also for any simplification of modeling and simulation.

Until now, the use of the complete

transfer equation was absent for scalar quantities. In contrast, numerous simplifications are

known, for example, used to describe the temporal dependence of molecular and

cellular reactions.

(13)

(13)

Model (13) is the most commonly used

mathematical expression (Terziev, 2012) To simplify equation, we introduced the term  , which

can take into account the effect of convection transfer Θ through the

always present in the liquid compressed product velocity field

, which

can take into account the effect of convection transfer Θ through the

always present in the liquid compressed product velocity field  :

:

(14 )

(14 )

Thus, the temperature and flow

fields caused by the effect of VT significantly affect the transformation of

any target component of the processed product.

Thus, the authors (Shazzo Kas'janov, 2000; Bohirov, Shcherbakov & Bakunova, 2013; Tsurkan, Gurich &

Polevoda, 2014) showed that these fields really significantly affect the inactivation of

microorganisms (Escherichia coli) and enzymes (Bacilius subtiiisα-amylase ) in packaged foods.

As

a modification for the processed products, it is necessary to solve

thermohydromechanical equations with appropriate initial and boundary

conditions in addition to the transfer equation (12) for each scalar

quantity. In all cases, models based on

these equations predict the existence of thermohydromechanical inhomogeneities

that cause differences in the number of surviving microorganisms, ie mortality

as a scalar quantity corresponds to equation (14).

In

the case of viscous plastics, the starting point is the thermal equation for

temperature T (K):

(15)

(15)

ρ = ρ (T,

P) density (kg / m3),

Cp = Cp (T, P) heat capacity (J / (kg.K),

k = k (T, P) thermal

conductivity ),

and tf time (s)

he

right side of the equation denotes an internal increase in temperature due to a

change in pressure. Here P = P (t) is the

pressure (MPa) created in the chamber, and α = α (T, P) is given as:

·

coefficient

of thermal expansion (K–1)

for the fluid that creates pressure in

the area ΩP*, 0, anywhere else.

This

condition is the result of the following law (Method for the

determination of total nitrite content (control method) (ISO 2918: 1975, IDT): DSTU ISO 2918, 2005 (Kotsiumbas, 2012; Zhuravskaya, 2015)

(16)

(16)

ΔT- temperature change

due to pressure change ΔP, V (m – 3) volume, m (kg) mass.

In the thermal conductivity equation (16), we finally took into account

the corresponding initial and limiting conditions depending on the design of

the equipment.

(17)

where n - the outer normal unit

vector at the boundary of the working area,

T0 - initial temperature,

Tr - the cooling or heating temperature that remains constant within the

known temperature Γr * (which cools or heats the food sample),

Tocr - ambient temperature (constant);

h W / (m2 • K) - heat transfer coefficient.

Since we used a

cylindrical coordinate system and axial symmetry, we rewrote the system (16,

17) as the following 2-dimensional problem:

(18)

(18)

This model is suitable

for the case when the filling factor of the food sample inside the chamber is

much higher than the filling factor of the pressure medium. If the fill factor of the food sample inside

the chamber is not much higher than the fill factor of the pressure medium, the

final solution with this model may be very different from the experimental

values.

As mentioned above, the

inhomogeneous temperature distribution is the cause of the inhomogeneous

density distribution in the pressure medium and, as a consequence, causes a

lifting force during the movement of the fluid.

In other words, free convection.

This movement of the fluid can affect the temperature distribution. To account for this fact, we used a

non-isothermal flow model. We

hypothesized that the flow velocity field, u (ms – 1), corresponds to the

Navier – Stokes equation for a compressed Newtonian fluid according to the

original Stokes premise and obtained the following system of equations:

(19)

(19)

where g is the

gravitational vector (m / s2);

η = η (T, P)

- dynamic viscosity (Pa• s); p = p (x, t) is the pressure that occurs during

mass transfer inside the liquid, and P + p is the total pressure (MPa) in the

medium that exerts the pressure.

It should be emphasized

that in the right part of the first equation (18) can be written  but we have made the

assumption that the internal heat resulting from mass transfer can be

neglected. In the right part of the

second equation we put

but we have made the

assumption that the internal heat resulting from mass transfer can be

neglected. In the right part of the

second equation we put  because P =

P (t)

depends only on time and therefore

because P =

P (t)

depends only on time and therefore  . Density

ρ = ρ (T, P) is a

fixed function of the state.

. Density

ρ = ρ (T, P) is a

fixed function of the state.

The system of equations (19) was

developed taking into account the corresponding points, limits and initial

conditions:

(20)

(20)

where

A1 - angular point Γp *, which is the boundary of the zone ΩP *.

It should be noted that the state of

point A1 means that the total pressure (P + p) at this point is equal to the

pressure in the chamber P plus atmospheric pressure. As shown above, for the model with heat

transfer due to thermal conductivity, the system of equations (18), the system

of equations (19) and (20) can also be rewritten as the equivalent of a

2-dimensional problem using cylindrical coordinates.

3.

CONCLUSIONS AND RECOMMENDATIONS

1. The kinetics of biochemical reactions depends

on the thermal, chemical and mechanical sensitivity of the processed product,

pressure, temperature and chemical potential.

2. One of the effective ways to

intensify the heat transfer process is the contact heating of the product by

means of steam, which has a technological impact on the processed products.

3. As a modification for the

processed products it is necessary to solve the thermohydromechanical equations

with the corresponding initial and boundary conditions in addition to the

transfer equation for each scalar quantity.

Modes of sterilization of meat pate from turkey

meat are offered, which were determined by the method in which the actual

lethality Ff relative to the microflora should be equal to or exceed the

required lethality of the sterilization process Fn (Ff ≥ Fn).

REFERENCES

Antipova, L.V. (2015). Research methods of meat and meat products. Kyiv: Kolos.

Belk, K. E., George, M. H., &

Tatum, J. D. (2012). Volatile

production in irradiated pale soft exudative (PSE) and dark firm dry (DFD) beef

under different packaging and storage conditions J. Animal Science, 79(3), 688–697.

Bogatko, N., Bukalova, N., Lyasota, V., Artemenko L., Bogatko, L., Bakhur, T., Prilipko, T., Zabarna, I., Savchuk, L., & Tkachuk, S. (2019).

Some indices’ determination of raw and pasteurized cow milk by ukrainian

manufacturers using unique express methods. Journal of Microbiology, Biotechnology and Food Sciences (JMBFS),

9(1), 9-14. DOI: 10.15414/jmbfs.2019.9.1.

Bohirov, V. V., Shcherbakov, G. N., & Bakunova, A. V. (2013). Theoretical

basis of heat engineering examples and problems. Proc. manual / FGOUVPO

"Ivanovo state energy University".

Ivanovo.

Buttriss, J. (2006). Hanging on the coat tails of the obesity epidemic: will

metabolic syndrome be the next public health

crisis and does nutrition have a role in its prevention? J.

Sci. Food Agriculture, 86, 2285–2289.

Chicken & Turkey Meat

Production in Canada—Market Research Report [Report]. (2019). Retrieved from

https://www.ibisworld.com/canada/market-research-reports/chicken-turkey-meat-production-industry/

Cherevko, O. I., & Poperechny, A. M. (2014). Processes and apparatuses of food productions: textbook. 2nd edition. Kharkiv: World of Books

Ibatullin, I. I., Zhukorsky, O. M., & Bashchenko, M. I. (2017). Methodology and organization of scientific studies in

creativity: a tool. Kyiv: Agrarian Science.Workshop On Feeding Farm Animals:

Educ. Tool.

Jemenez-Colmenero, F. (2007). Healthiner Lipid formulation approaches in meat − based functional foods. Technogical options for, replacement of meat fats by non-meat fats. Trends

Food Sci. and Technol., 18, 567–578.

Kaletnik, G. M., & Yanovich, V. P. (2017). Prospects of development of vibrating machines for

primary processing of agricultural raw materials. Vinnytsia:

Vinnytsia

National Agrarian University. (in Ukrainian)

Kilincceker, O., & Karahan, A.

M. (2020). The effect of buckwheat flour on some quality properties of chicken

meatballs as an alternative to wheat flour. Ñarpathian journal of food science and technology, 12(4), 155-164.

Kotsiumbas, H. I., Shcherbakovska, O. M., & Kotsiumbas, I. Ia. (2012) Ekspertyza kovbasnykh vyrobiv histolohichnym metodom. Lviv. 103 p. (in Ukranian)

Lynchab, S. A., O'Neill, A. M.,

Drummond, L., & Álvareza, C. (2018). Opportunities and perspectives

for utilisation of co-products in the meat industry. Meat Science, 144, 62–73. DOI:

https://doi.org/10.1016/j.meatsci.2018.06.019.

Meat and Meat Products. (2005). Method for the

determination of total nitrite content (control method) (ISO 2918: 1975, IDT): DSTU ISO 2918:

2005. Effect from 2008-01-01. To: State

Consumer Standard of Ukraine, 2010. 10 p.

(National Standard of Ukraine).

Palamarchuk, I. P., Polyevoda, J. A., & Kutsyi, V.

M. (2017). Matematychne modeliuvannia protsesu teplomasoobminu za umov parokontaktnoi sterylizatsii produktsii u tsylindrychnii tari [Mathematical modeling of

the process of evaporation in terms paracontact sterilization in cylindrical containers]. Tekhnika, enerhetyka,

transport APK, 64-70.

Prilipko, T. M., & Kuts, V. M. (2013). Patent No. 83518, Ukraine ÌÏÊ9 AND 23Â4/00. Canned

pate from the meat of turkeys. No. u201304965; Appl. 18.04.2013; publ. 10.

09., bull. No. 17/2013.

Prylipko, T.,

Bukalova, N., & Lyasota, V. (2019). Features of the introduction of the

HACCP system on enterprises of Ukraine. The potential of modern scienct. London, 1, 49-60.

Prylipko, T., Koval, T., Kostash, V., Tocarchuk T. &

Tsvihun, A. (2020). Îptimization of recipe turkey meat pate. Ñarpathian journal of food science and technology, 12, Nr.(4), 98-112.

ISSN-L2066-6845.http://chimie-biologie.ubm.ro/carpathian_journal/index.html

Terziev, S. G. (2012). Elektrodiffuzionnaya model teplomassoperenosa v termosifonnyih apparatah. Nauk. pr. ONAHT, 41(1), 219–222.

Terziiev, S. H., Malashevych, S. A., & Ruzhytska, N. V. (2011). Doslidzhennia protsesu sushinnia shlamu kavy pid diieiu infrachervonoho vyprominiuvannia. Naukovyi

visnyk Lvivskoho natsionalnoho universytetu veterynarnoi medytsyny ta biotekhnolohii im. S. Z. Gzhytskoho,

13(4) (50), Ch. 4, 131–134.

Tsurkan, O. V., Gurich, A. Y., & Polevoda, Y. A. (2014). Substantiation of

technological and constructive schemes of the autoclave with an aerodynamic

intensifcation. Scientific works ONAFT, 2(46). p.

Voronenko, Â. À. (2008). The mathematical description of processes of heat

and mass transfer in meat products during their heat treatment. Processes and equipment of food

productions, 2, 27-30.

Yakubchak, O., Melnichuk, S., Zvon,

A., & Deineko, E. (2014). HACCP - an effective preventive system for guaranteeing food safety. Meat business, 7(25), 68–69.

Zhang, R. et al. (2016). Effect of oral administration of probiotics on growth

performance, apparentnutrient digestibility and stress-related indicators in

Holstein calves. Journal of Animal

Physiology and Animal Nutrition, 100 (1), 33–38.

https://doi.org/10.1111/jpn.12338.

Zhuravskaya, N. K., Alekhina, L. T., &

Otryashenkova, L. M. (2015) Research and quality control of meat and meat

products. Moskow: Agropromizdat. (in Russian)

MODELING

OF MICROBIOLOGICAL AND BIOCHEMICAL PROCESSES UNDER THE CONDITIONS OF STEAM

CONTACT STERILIZATION IN CONTAINERS OF TURKEY MEAT PATE

MODELING

OF MICROBIOLOGICAL AND BIOCHEMICAL PROCESSES UNDER THE CONDITIONS OF STEAM

CONTACT STERILIZATION IN CONTAINERS OF TURKEY MEAT PATE