BIOLOGICALLY

STRUCTURED MATERIALS

Relly Victoria V. Petrescu

Bucharest Polytechnic University, Romania

E-mail: rvvpetrescu@gmail.com

Raffaella Aversa

Department of Architecture and Industrial Design,

Second University of Naples, Italy

E-mail: raffaella.aversa@unicampania.it

Antonio Apicella

Department of Architecture and Industrial Design,

Second University of Naples, Italy

E-mail: antonio.apicella@unicampania.it

Florian Ion Tiberiu Petrescu

IFToMM, Romania

E-mail: fitpetrescu@gmail.com

Submission: 25/06/2019

Accept: 26/06/2019

ABSTRACT

In this paper bio-tissue mathematical modeling serves as a central

repository to interface

design, simulation, and tissue fabrication. Finite element

computer analyses will be used to study the role of local tissue

mechanics on endochondral ossification patterns, skeletal morphology and mandible

thickness distributions using single

and multi-phase continuum

material representations of clinical cases of patients implanted with the traditional protocols. New protocols will be hypothesized for the use of the new biologically techno-structured hybrid materials.

Keywords: Biologically Structured Materials; Techno-structured materials Hybrid materials; Biotechnology; Bioengineering; Biomaterials, Bioactive scaffolds, Biomimetics, Endochondral ossification patterns; Finite Element

Analysis, Osteointegration, Skeletal

morphology, Tissue mechanics

1. INTRODUCTION

Biomimetics, biomechanics, and tissue engineering are three multidisciplinary fields that have been contemplated in this research to attain the objective

of improving prosthetic

implants reliability. Since testing and mathematical methods are closely

interlaced, a promising approach seemed to be the combination of in vitro and in vivo experiments with computer

simulations (in silico).

An innovative biomimetics and biomechanics approach, and a new synthetic structure providing a microenvironment, which is mechanically coherent and nutrient

conducive for tissue

osteoblast cell cultures used in regenerative medicine, are presented.

The novel hybrid ceramic-polymeric nanocomposites are mutually investigated by finite element analysis (FEA) biomimetic modeling, anatomic reconstruction, quantitative-computed-tomography characterization, computer design of tissue scaffold. The starting base materials are a class of innovative highly bioactive hybrid ceramic-polymeric materials set-up

by the proponent research

group that will be used as a bioactive matrix

for the preparation of in situ bio-mineralized techno- structured porous

nanocomposites.

This study treats biomimetics, biomechanics and tissue engineering as strongly

correlated multidisciplinary fields

combined to design

bone tissue scaffolds. The growth,

maintenance, and ossification of bone are fundamental and are regulated

by the mechanical cues that are imposed by physical

activities: this biomimetic/biomechanical approach will be pursued

in designing the experimental procedures for in vitro scaffold

mineralization and ossification. Bio-tissue mathematical modeling serves as a central

repository to interface

design, simulation, and tissue fabrication.

Finite element computer analyses will be used to study the role of local tissue

mechanics on endochondral ossification patterns, skeletal morphology and mandible

thickness distributions using single and multi-phase continuum material representations of clinical cases

of patients implanted with the traditional protocols. New protocols will be hypothesized for the use of the new biologically techno- structured hybrid materials.

It is known that the field of interdisciplinary research

of materials for biomedical applications is structured and calibrated today in the bone repair study, which is basically its basis.

The bones are considered to be a biological hybrid material

composed of an organic

component, collagen, and an inorganic nanocrystalline hydroxyapatite component. Both phases integrate on a nanoscale so that morphological and physical variables such as crystal

size, nano-orientation, short-order order

between the two components determine the characteristics of its nanostructure and therefore the mechanical properties of the different

types of bone Frost, 1964, 1990,

2004).

Based on bone regeneration criteria, new bioactive

biomaterials have been developed. These materials are expected

to favor the formation of bone tissue by stimulating the proliferation and differentiation of osteoblasts (SCHIRALDI et al., 2004; AVERSA

et al., 2016a; AVERSA

et al., 2016b; AVERSA

et al., 2016c; AVERSA

et al., 2016d; AVERSA

et al., 2017a; AVERSA et al., 2017b, 2019; SYED et

al., 2017).

The use of nanostructured materials similar to natural bone tissue is one of the most

promising options for bone healing.

Nanotechnologies for the implementation

of

organo-inorganic hybrid materials offer excellent chances to improve

the performance of existing

conventional bone implants

(AVERSA et al., 2016a; AVERSA

et al., 2017).

Current research evaluates the evolution of polymer-polymer hybrids for bone tissue repair, as well as chemical procedures that control

the nanostructuring of materials.

1.1.

The

objective of the paper is inherent in the following scientific fields;

· biomechanics and human biophysical

bone,

· Biomimetics: nanotechnology in

medicine for materials inspired by nature

·

Bioactive

scaffolds favoring osteointegration in nanocomposite and hybrid porous

structural matrices

1.2.

Biofidelity

advances

Recent studies of the mandible

(SCHWARTZ-DABNEY; DECHOW 2003, APICELLA et al., 2010; AVERSA et al., 2016a; AVERSA et al., 2016b) and FEM modeling

of teeth (SORRENTINO et al., 2007,

APICELLA et al., 2015).

Knowing the mechanical and adaptive features of the bone is an

essential issue in designing

new biomimetic prostheses to replace

a bone with minimal biological and biomechanical

invasiveness.

Biomimetics is the science

that investigates such aspects

and can be considered the natural junction between biology

and engineering. This competence convergence allows

the development of biological principles and models to produce

bio-inspired materials that can be used

to

fully design prosthetic tissues

and systems.

New generations of concepts could be generated by the

conscious investigation of biomimetics, which can provide clinical tools to restore the structural, biomechanical and aesthetic integrity of bone functions.

Recent advances in cellular

and molecular biology and material

engineering science

(nanotechnology) have established that biomimetics and tissue engineering are developed

to improve the integral integration of prosthetic and restorative implants (AVERSA et al., 2016a; AVERSA et al., 2016b; AVERSA et

al., 2016c; AVERSA et

al., 2016d; PERILLO

et al., 2010; ANNUNZIATA et al.,

2010).

Since last century,

parts of our body have been replaced

with artificial prostheses. The materials used for these devices

were chosen not to produce

adverse responses

in contact with human body tissues and physiological fluids.

The criteria for choosing a specific

biomaterial were related

to its biocompatibility and functionality, which could be directly

associated with interfacial bone/implant interactions at a nanometric level. Only in the 1990s, the study of these interference effects

was improved by the use

of thin nanometer

layers and surface changes.

It then generated

a great commercial interest in the orthopedic market of adopting new modified implants of nanoparticles

that promote soft and soft tissue

engineering.

1.3.

New

classes of Biomaterials

There are several ways in which living tissues

can react to synthetic implant materials,

but are essentially limited to their response

to the

interface material

Three main terms could describe

the behavior of biomaterials defined by Jones et al (2012),

Hutmacher (2000) and Hoppe (2011).

Namely,

tissue responses are divided

into:

• Bioinert

• Bioresorbable

• Bioactive

A further

classification of ceramic biomaterials can be made according to their reactivity to physiological fluids;

• bioinert, such as

Alumina for dental application;

• bioactive, such as

hydroxyapatite used as a coating on metallic

implants,

• The

active surface, such

as bio-glass or A-W bottles,

• bio-resorbed, such as tri-calcium phosphate

Further improvement of these properties can be accomplished using nanostructured

bioceramics that can be used as interactive

materials, helping natural

tissues heal by promoting tissue

regeneration and restoring physiological functions (SCHIRALDI et al 2004; MANO et al., 2004; MORALES-HERNANDEZ et al., 2012; MOURIÑO et al.,

2012).

This approach has been studied in this study to develop a new generation of nanostructured bio-ceramic-polymeric hybrids that can be used in a wider range of medical applications (PETRESCU; CALAUTIT, 2016a;

PETRESCU; CALAUTIT,

2016b; PETRESCU et al., 2015; PETRESCU et al., 2016a; PETRESCU et al., 2016b; PETRESCU

et al., 2016c; PETRESCU

et al., 2016d; PETRESCU et al.,

2017; PETRESCU et al., 2018).

Porosity is one of the keys to the success

of these materials and is increasingly adopted when

a narrowing of the bones is required

and strong implant stability.

1.4.

Tissue

engineering new perspectives

For several years, tissue engineering has benefited

from the combined

use of live stem cell intake in three-dimensional ceramic scaffolds.

This strategy

is completed to provide healthy cells directly to the damaged site (BONFIELD

et al., 1981; HENCH, 1993; HENCH, 2002; HENCH,

2010).

By

combining the traditional bio-ceramic implant with the already assimilated knowledge of stem cell growth and differentiation in clinically and productively developed osteogenic strategies.

Stem cells developed in ceramic nanobiocomposites should be adopted

in the case of extensive bone repair

with excellent prospects of good functional recovery and integration of

the hybrid

scaffold with bone.

Synthetic Hydroxyapatite (HAp) has been described

in the literature as an attractive material

for bone implants (KIM et al., 2004; MORALES-HERNANDEZ et al., 2012).

Since its adoption,

the most common and simplest

method of producing synthetic HAp is the solid reaction

between calcium and phosphate

ions, resulting in the formation

of powdered compounds which can be sintered

and recovered at elevated

temperature to form a compact polycrystalline structure

Julien 2007).

The HAp bioactivity is governed

by processing parameters, such as the initial

compounds, the size of the crystalline granules, their purity, and the ratio of calcium

to phosphorus atoms. In particular, nanocrystals have shown improved bioactivity due to their large surface area. The use of hydroxyapatite with nanoparticles has been proposed as a valid solution

for the consolidation of low strength

polymer scaffolds.

The use of HAp nanoparticles for new classes

of implants, biocompatible coatings, and high strength

nanocomposites can be developed (GORUSTOVICH et al 2010).

1.5.

Biomimetics

A

general feature

of several tough natural hybrid materials, such as bones, sea urine teeth, pearls, is the strong nanometric interaction between inorganic

and organic phases.

This feature allows the organic

phase to act as a nanometric scale as a plastic energy dissipation network that inhibits crack propagation (high resistance); s, in situ synthesis techniques, have been adopted to mimic naturally

occurring processes.

In particular, precipitation of hydroxyapatite (or other crystalline compounds) in a polymeric

matrix was considered a viable route to

produce biomimetic

composites.

1.6.

Organic-Inorganic

Hybrid Biomaterials

A

bioinspired material development approach considering the formation

of self- assembling hybrid organic-inorganic will favour the use of hybrids

in biomedical applications. The high versatility of these hybrids

offers main functional and structural advantages that lead to the possibility to tailor-design materials

in terms of shape,

and chemical and physical properties.

1.7.

Bioengineering

and Bioactive scaffolds

For nanotechnology nanomaterials, nanotechnology is increasingly adopted for emerging

applications such as coating systems or three-dimensional coating systems (tecto)

(AVERSA et al., 2016a; Karageorgiou et al., 2005; SORRENTINO et al., 2007). Critical,

micro and nanotechnologies show the potential to be used to produce

advanced models for fundamental studies, such as tissue engineering structures or bio-molecular

devices.

The

ideal material for bone

skeletons has always been a hot

topic for research. An ideal skeleton should provide a sufficiently rigid but durable

mesh to temporarily replace

the damaged bone. At the same time, it should be able to biodegrade after the formation

of new tissues and integrate

it fully (MONTHEARD et al., 1992; KABRA et al., 1991;

PELUSO et al., 1997; SCHIRALDI et al., 2004).

Amorphous nanoparticles were synthesized in the laboratory. A new class of polymer-ceramic hybrid materials simulating the mechanical behavior of the bone were used as potential candidates for scaffolding (SYED

et al., 2017).

The result of these self-assembled nanostructured composites was micro-foamed and tested as a new preimplantation skeleton that can accommodate osteoblast growth factors

or stem cells to differentiate osteoblasts.

1.8.

Biofidelity

models and FEM analysis

Understanding the biological mechanisms of healthy and healthy bone growth is an iterative process between

biology and engineering. During this process, knowing that reverse

engineering of a biological system can have positive feedback in the field of biology,

allowing for a more complete and secure understanding of the potential

path for further development

of applied medical

engineering.

The most important question is how clinician interference with biological systems

can be optimized to improve

treatment options

so as to increase treatment

efficiency and lead to a

more stable outcome.

The use of new diagnostic and engineering tools such as those used in our research

(for example, CT and CTM CT segmentation and solid CAD reconstruction) can detail the anatomy of soft and soft textures in a very precise manner as a small standard

deviation. Therefore, the integration of biological knowledge and clinical possibilities is essential. A more reliable and biophysical model begins with biomechanical

modeling of bones, ligaments

and alveolar bone,

using Finite Element

Analysis to gain insight into the biological response to changing biomechanical circumstances.

Because current tests and numerical methods

are closely related, a methodological approach is to combine in vitro and in vivo experiments with computer

simulations (in silico). There are, however, a number of stimulus

points involved in creating and realizing the mathematical

model. The concurrent interaction of several

variables that influence

the prosthetic system was investigated by simulation in the mathematical modeling of finite

elements.

Finite Element Analysis (FEA) involves the subdivision

of a

geometric model into a finite number of elements, each with specific

mechanical properties. The variables

to be investigated are guessed

with mathematical functions. Specific mathematical software evaluates the distribution of stresses and stresses in response

to changing charging conditions.

A complete

assessment of the mechanical behavior of a solid or prominent

biological structure

can be made, even in the case of non-homogeneous organisms. When properly validated by in vivo or in vitro testing, finite element

analysis is useful in defining

optimal recovery criteria and material

selection criteria

while allowing for potential

fracture prognosis in limited circumstances.

2. METHODS AND MATERIALS

2.1.

Materials

The hydrophilic matrix for amorphous silica amorphous filler

(Aerosil 300 Degussa, Germany) of 7 nm with a specific

surface area of 2 n-hydroxyethyl methacrylates (HEMA), Sigma-Aldrich Chemicals Co., was used. 300 m2g-1.

The initiator of the radical polymerization reactions used as azoisobutyronitrile (AIBN) obtained

from Fluka (Milan, Italy). HEMA monomers were mixed

with 10% by volume of silica.

The degassed resin was poured

into 2.5 mm thick flat molds and polymerized at room temperature, controlled

at 60 ° C for 24 hours. Another end of 1 hour at

90 ° C was finally made on

the nanocomposite plates.

Microporosity was induced in the dense material

by first balancing the samples in pure ethyl alcohol and then rapidly extracting the alcohol absorbed

by balancing into distilled water. During the rapid extraction of alcohol and counter-diffusion, a microporosity occurs in the ceramic-polymer hybrid material,

evidenced by the intense

bleaching of the treated system.

2.2.

Finite

Element Analysis (FEA)

Segmentation of medical images was derived from CT using the Mimics software

(Materialize, Belgium) to process a medical image to the patient.

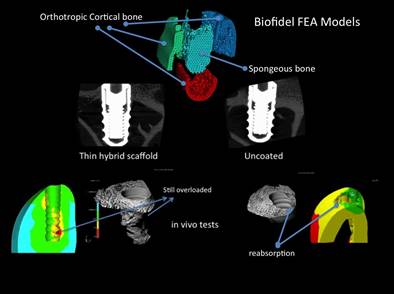

As reported at the top of Figure 1, CT processing has led to a solid 3D solid model of anatomy and bone structure.

The combined use of Mimics and 3-Matic software (Materialize, Belgium) has been used

to obtain solid 3D models and Finite Element Analysis

(FEA).

External bone geometry was reconstituted by generating a three-dimensional volume that interpolates CT scans. The results were then imported

into the 3Matic

software for surface

and solids optimization, finite

element modeling and material properties of different sections

of the bone according to the characteristics of the literature (BEAUPRE; HAYES, 1985; REILLY; BURNSTAIN, 1974; REILLY; BURNSTAIN, 1975; HUISKES et al., 1987; SCHWARTZ et

al.; DECHOW, 2003; TÖYRÄSA

et al., 2001).

Bone stress can be modulated by choosing skeletal

swollen thickness for healthy

bone growth. In vivo tests performed using these

modified oral implants

confirmed the improved ability of these implants

to promote early osteointegration (GRAMAZZINI et al.,

2016).

Biomimetic/biomechanical

approach: Ceramic-polymer hybrid design

and

bulk design to improve osteointegration Bioprotective devices are widespread rehabilitation therapy in clinical

practice in many areas of rehabilitation surgery such as dentistry, maxillofacial surgery, orthopedics. The bone and implant

interface has been studied

for many years as we try to move from bioinert to bioactive

biomaterials.

In fact, the histological analysis carried out in these years does not allow confirmation of possible

contact theories, junction systems, and others. But there is fluid contact between the osteocyte channel and the implant surface. Bioactive biomaterials could favor and amplify

differentiation from an osteoblastic phenotype that occurs during healing

of surgical wounds caused by the implant,

with better osteointegration at shorter times. Recent studies

describe the characteristics of nanostructured materials that could

promote osteointegration:

·

Carbon and alumina

nanostructures, which mimic nano-dimensional geometry of hydroxyapatite, increase osteoblastic activity and thus produce larger bone deposits when

applied to orthopedic implants.

·

nanostructured biomaterials that mimic the bioactivity of hydroxyapatite crystals favor

the adhesion and production of

alkaline phosphates in osteoblast-like

cells

Therefore, further studies on these materials

could bring better and shorter

healing to promote

protocols to ensure early and immediate loading. The composition and the surface properties appear to be important

because they seem to modulate the response of the osteoblast cells affecting tissue healing

(DAVIS et al. 1991;

GRAMAZZINI et al., 2016; AVERSA, 2016b).

The implanted tissue adjusts its composition and architecture to its functional load (APICELLA et al., 2011; APICELLA et al., 2015). Therefore, a key to the success of the titanium implant to integrate

into the bone appears

to be whether bone remodeling is correct or not on the periphery of the implant

(AVERSA et al., 2016b).

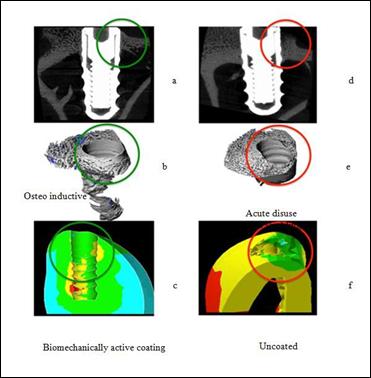

Figure 1 shows the result of "in

vivo" experiments performed on dental implants

placed in rabbit white femur. In particular, the experiment described in Aversa et al. (2016b)

consisted of assessing the osteoinductivity and osteoconductivity of the Ti implant surfaces

without a 100-microns thin-layer ceramic-polymer hybrid material.

Bone implantation or bone thickening (COMERON, 1986), which is defined

as the percentage of bone implants for biomimetically implanted implants and not covered

by the six-month in vivo test, shows a significant improvement in approximately 100% growth over

two months, and 30% after 6

months.

The reconstruction of the bone micro-CT

bone around the implant

was validated using the physiological distributions of the calculated FEA strains. Maps of the maps surrounding the bone around the implant confirmed the critical role of the Ti-Bone

bioactive interface.

Osteoblast proliferation and bone growth in the implanted rabbit femur are clearly

favored and accelerated

by the presence of the

hybrid nanostructure layer.

The biomechanical approach utilizing adaptive bone properties describes the biomimetic behavior of the proposed

preimplantation hybrid scaffold as it can predict

bone resorption surfaces (elements of the FEA model with strains

below the lower physiological boundaries were deleted in the image) as shown in the in vivo implant

micro reconstruction microtubule on the right

side of Figure 1).

Figure 1: in silico and in vivo validation for

Osteoconduction of Titanium implants coated with a nanostructured hybrid osteoactive (left side) and without (right).

Research has shown that mechanical stimulation can have a profound effect on the differentiation and development of mesenchymal tissues.

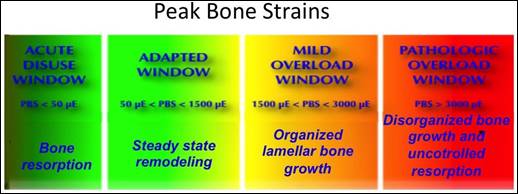

Figure 2 illustrates the adaptive properties and strain threshold

values for healthy

bone growth.

Figure 2: Adaptive window of bone physiology:

Structural adaptations to mechanical usage

Source: Frost (1990)

According to Frost (1990),

which quantified Wolff (1892)

above (> 3000 micro epsilon) and below (<50 micro epsilon)

of critical strain levels,

bone growth is impaired. In the mild strain region, healthy bone growth and regeneration is favored.

In fact, in order to maintain implant stability during pregnancy, it is of major importance for bone-forming osteoblasts to promote an extracellular matrix in the immediate vicinity of the implant.

Osteointegration mechanisms to be considered in biofidel models

Osteointegration of implants is essential for the rehabilitation of the prosthesis. Achieving and maintaining stable functional anchylosis has the following morpho- structural characteristics, namely:

·

direct contact between bone

and implant in the absence of the idoneous tissue interface;

·

the existence of the primary bone

in contact with the surface of the biomaterial;

·

deposition, externally to the

primary bone, of the lamellar secondary bone in contact with the titanium

surface;

·

increase in preimplantation

bone density compared to the normal bone region of the region;

·

Increase in medullary spaces,

which is required to evacuate the metabolic requirements of less involved

tissues in the region in the dissipation of the load;

·

Compact bone condensation,

which may be related to the load propagation patterns determined by the specific

morphology of the implant;

·

organizing a strong trabecular

structure that is radially removed from the compact preimplantation bone;

·

the presence of a bone crystal

wall at the level of the subepithelial conjunctiva, which may allow junctional tropism

and the formation of the liquid epithelium.

The mature matrix, which

has been described to occur in dental and orthopedic clinical trials,

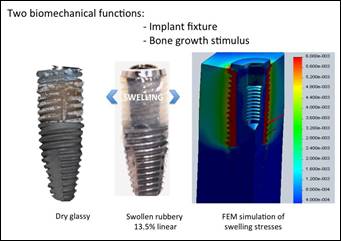

is expected to provide mechanical stability of the implant even in the early osseointegration phase (primary stability). In fact, due to the hydrophilic nature of the hybrid material, high fluid levels are absorbed from the external fluid medium,

resulting in significant swelling and an initial increase

in the volume of hybrid glass material (Figure

3).

Figure 3: Mechanisms

of primary stability

and osteoinduction improvements

in Hybrid swellable scaffold modified Titanium implant. Glassy dry

scaffold (left)

The biomechanical and biomimetic active scheme has two biomechanical functions, the first being strictly related

to stabilization of the prosthetic system after implantation (the prosthesis can be loaded one hour after implantation), while the second function

is associated with stimulation of bone growth exerted by implanting the bone surface from

around her.

The volumetric expansion of the scaffolding can be effective in improving

the stability of the primary implant,

confirming the high bioactivity of the nanocomposite material tested (Figure 4), (PETRESCU; PETRESCU, 2019;

PETRESCU, 2019).

The presence of the inflatable implant component, which is supported by the upper part of the Ti core of the implant, increases the removal torque after

implantation when the system is in the

presence of organic fluids.

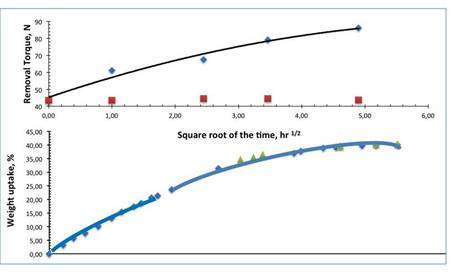

Figure 4: Physiological fluid uptake (bottom) and

implant stability improvement (top) of Hybrid swellable scaffold modified

Titanium implant.

The removal time, measured at different times after implantation, actually increased by more than 100% to 24. In addition,

even after one hour, the removal

torque already increased

from 43 to 62 N (an improvement of approximately 25%). It has been described in a previous

paper (AVERSA et al., 2016b) that improved retention has immediately followed the spinning kinetics of the hybrid material scaffold

(bottom of

Figure 4).

This increase in implant

stability is due to the strong compression strains generated in the swollen rubber hybrid scaffold,

as can be deduced from the map of the stained strains reported on the right side of Figure 3 (the red color of the implant hybrid insert).

The implant is then constrained in its socket by the external bone, which then increases

the retention and stability

of the implant.

Applying a larger

removal torque for explants

is, therefore, necessary

to increase the experimentally measured inflation

rate.

Furthermore, the constraint bone is subject to expansion strains as indicated by the colored map of the Von Mises strains reported

in Figure 3. The color scale used for this map is the same as that reported

in Figure 2, the physiology in which healthy growth and induction

correspond to colors of yellow and green and blue and red to bone

reabsorption.

The surrounding bones are subjected to healthy

bone deformation at a distance equivalent to the diameter of the implant. In this toroidal volume surrounding the implant,

an osteoinductive effect and a faster osteointegration of the implant

are expected.

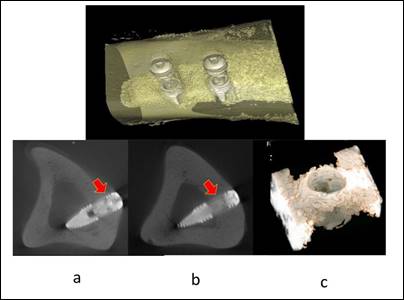

A micro-computer

tomography confirmed these expectations.

Figure 5 shows the

micro CT of these volumes.

Figure 5: The Bone to Implant Contact (BIC) and the

relative bone density have shown similar characteristics at cortical (a) and

medullar levels (b), Bone near to the implants shows similar characteristics

(c)

Souce: Gramanzini

et al. (2016)

The upper part of the figure

reports bone reconstruction and external implants, while the lower part shows the 3D reconstruction of the volume surrounding an implant.

BIC and relative bone density had similar characteristics at cortical

(a) and medullary

(b) levels indicating good osteointegration of the initial bone implant.

The newly formed bone near the implanted implants has similar characteristics to the preceding (c), indicating the biomechanical stimulation effect of the swollen

and swollen hybrid material.

Traditional bone prostheses are mainly made of metals and ceramics

with remarkable strength

and stiffness, but with

high physiological invasiveness.

These implants, which are expected to serve for a longer

period of time, without failure

or surgical revision, although they guarantee mechanical and functional wood, occur frequently physiologically and mechanically with the human bone. Failures and lack of long-term reliability result

from incomplete integration of the personal characteristics

of the

bones and the patient

with local physiology.

To

reduce implant invasiveness, a biomimetic approach is suggested; the implant is expected

to have an "equivalent stiffness" (the combination of the elastic modulus of the material

and the prosthetic shape) that matches that of a bone area where it is implanted.

The bone modulus varies in size from 4 to 30 GPa, depending on the bone type and the direction

of measurement (bone

orthotropy). Current implant implants are isotropic with higher rigidities than bone (for example, between 160 and 210 GPa for titanium and steel alloys) that greatly

alter the physiological distribution of bone stress.

This behavior prevents the transfer

of biomechanically modified

stress to the adjacent bone, resulting in bone resorption around the implant

and, consequently, weakening

of the implant (this effect is

called stress reduction).

This unwanted biomechanical invasiveness is due to the fact that the bones are functional and structural complex

entities composed

of less rigid,

open and dense and rigid materials that

are combined to

provide rigidity both in orthotropic

forces and in cortical bone forces. Equivalent to the three-dimensional properties of bone tissue should be truly necessary for implanted

prostheses to achieve complete integration into the host bone tissue

(AVERSA et al., 2019).

However, for the replacement and regeneration of soft tissues

and osteoconductive and powerful mechanisms, porous and ceramic

metallic biomaterials and polymeric systems and other metals have been proposed (TAYLOR et al.,

2007; PARFITT, 1983;; PARFITT,

1994; MARTIN et al.,

1998).

From a biomechanical point of view, the structure

must be rigid enough to support physiological tasks,

but should not drastically exceed the stiffness

of the replaced

bone to avoid stress shielding. Attaching the implant to the surface

or to the bone matrix should be

improved by alternatives to reduce stress protection.

Clinical efficacy and long-term

reliability of bone prostheses have been thoroughly investigated by analyzing

finite elements to clarify the causes of the new replacement of invasive restoration (GRAMANZINI et al., 2016; AVERSA et al., 2016a; AVERSA et al., 2016b).

Figure 6 summarizes the main methodological steps

used in these studies:

(a) biophysical bone for investigation, (b) highlighting and weighing

fractured bone macroanalysis, (c) stress of microanalyses and strains on the bone-implant interface. The peak values and regions

of adaptive bone properties are shown in Figure 6d where unused, healthy and overloaded regimens are reported

in Figure 6d (FROST, 1990).

Bone prosthesis interference was recognized at two magnitude

levels, namely a micro scale (bone-implant interface, Figure 6c) and a macro

scale (Figure 6b).

The first small scale (Figure 6c) explains

the biological and micro-mechanical interactions of the synthetic biomaterial with bone-forming cells and highly adaptive adaptive properties, while the second on a macro scale (Figure 6b) determines the complete biomechanical functionality of the implant

material and the ability to restore the distribution of the biologic stress state in the

prosthesis.

Osteoblasts under specific biochemical and mechanical stimuli mature

and turn into osteocytes that mineralize the bone. The activity of osteoclasts under conditions that were not stimulated mechanically after prostheses could induce bone reabsorption in this new state of

mechanical equilibrium.

Figure 6d shows the adaptive

bone properties that are in the coupling between bone

formation and bone

reabsorption.

(a) (b) (c)

(d)

Figure 6: Finite element analysis tools for

biomechanical and biomimetic investigation: (a) Biofidel models of the bone,

(b) Macro Finite element analysis of the implanted bone for definition of the

stresses and strains physiological modifications, (c) Micro Finite Element

Analysis at the bone-implant interface, (d) Strain limits for bone adaptive

properties.

Source:

Frost (1998)

This process refers to bone formation in which osteoclast reabsorption via osteoclasts and renewed osteoblast generations of precursors dynamically replace

dynamics (Figure 7).

The coupling can then be considered a complex mechanism of dynamic remodeling involving interactions of different types of cells and control

stimuli. Mechanical stimulation should include physiological levels of the strain (Figure

6d) between 50m and 3000m (APICELLA et al., 2011; APICELLA

et al., 2015; AVERSA et al., 2009). Over 50 years

of osteocyte activity predominate, resulting in bone resorption of between 1500 and 3000 m, a slight increase

in lamellar bone,

predominantly over 3000,

with uncontrolled bone

growth or resorption.

3. RESULTS AND DISCUSSION

In the case of bone, which is a structural biological material

that undergoes a mechanically induced continuous renewal (Figure 7), the remodeling process

is controlled by a dynamic balance involving osteoclasts (linking bone cells) and homeostatic

renewal osteoblasts.

Osteoblasts under specific biochemical and mechanical stimuli may actually mature and turn into osteocytes that mineralize the bone. Instead, osteoclastic activity under conditions that were not stimulated mechanically after the prosthesis (ie in the stress

release area) could induce bone reabsorption in this new state of bio-mechanical

balance (Figure 7).

Figure

7:

Bone homeostasis mechanism

involving Osteoblast,

Osteocyte and Osteoclast

cells

Thus, in order to favor biomechanical integration and a longer maintenance period, a customized material, which carries

a great combination of high strength

and stiffness that fits the bone, must be used. The use of trabecular scaffolds and cortical bone to mimic behavior

and colon have been proposed

to recreate the distribution of macroscopic stress

and bone deformities but requires a necessary

micro-biomimetic interface that interacts with osteoblast osteoblasts.

Nanomaterials Ceramic-polymer nanoparticles based on hydrophilic and ceramic

polymers are potential candidates for new customizable biomaterials that will be used to cover porous phosphorus structures. The hybrid layer that comes into contact with bone can be customized by choosing nanophysics content and mechanical properties to achieve

the biomechanical characteristics necessary to increase

thickening of the osteoinductive bone in the porous

structure of the metallic

prosthesis.

These resulting hybrid systems

have the basic mechanical and biological properties that favor local healthy local generations. Specific and adjustable properties that simulate

bone tissue that acts on the interface guide microparticle, leading to bone marrow

growth and integration into host bone tissue. The main reasons for using the skeleton are therefore

to provide a bone formation environment, maintain space and support

the skeleton of the skeleton

during the repair process.

New

biomaterials that possess hybrid characteristics can be obtained by using nanometers in polymeric

matrices (AVERSA

et al., 2016a; AVERSA et al., 2017a;

AVERSA et al., 2017b), especially carbon nanofillers such as fullerenes and carbon nanotubes have been proposed to increase

strength and

stiffness nanocomposite materials. Although the use of carbon diamond

nanofilm can further

improve these

properties, some technological challenges

in production

technology should be overcome.

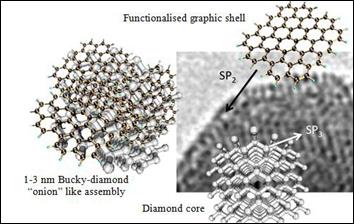

Graphite is only one of allotropic carbon forms and is thermodynamically stable at ambient temperatures and pressures, while the diamond

is another stable allotrope carbon

at high pressures

and at a temperature present in a metastable state at ambient

and similar conditions (PETRESCU; CALAUTIT,

2016 a-b).

Differences in the stability of allotropic forms are a consequence of the large energy barrier separating the graphite

Sp2 (left in figure 8) and diamond

sp3 configuration (even in figure 8), which requires

high temperatures and pressures in the presence

of the transformation catalyst.

However, an additional equilibrium parameter involving the surface

becomes critical and significant for the distribution of the equilibrium energy to the nano dimension: Gibbs free energy is drastically influenced by the presence of surface energy input, modifying

the phase diagram of the thermodynamic equilibrium (BADZIAG et al.,

2003; BARNARD et al., 2003; BARNARD; STERNBERG, 2007; VIECELLI

et al., 2001).

Atomic models (PETRESCU; PETRESCU, 2019; PETRESCU, 2019) have demonstrated that nanodiamonds with 3 nanometers with tetrahedral hydrocarbons are more stable than polyaromatic graphite under ambient conditions

(BADZIAG et al., 1990; AVERSA et

al., 2016a; AVERSA et

al., 2016b; AVERSA

et al., 2016c; AVERSA et

al., 2016d).

The presence of a more complex

structure, generated

at the nano-diamond interface, opens

up new interesting technology

applications. Cuboctodic structures

of 1.03 to 3.0 nm with onion structure characterized by the passage from Sp3 to Sp2 carbon

at their surfaces

were observed by Barnard and

Sternberg (2007).

A reversible reverse phase transformation in a nanodiamond-graphite cluster was observed

by Xiao et al. (2014)

appear in this morphological transition interface, which leads to daily bucky formation, characterized by a diamond core, a graphical case (schematized in Figure 9) (BARNARD;

STERNBERG, 2007). Such graphite

nano- diamond surfaces

can be modified

using graphite carbon chemistry to form cyclohexane functional systems such as Diels-Alder cycle reactions

between a conjugated diene and dienophiles (JARRE et al., 2011).

The nano-crystalline Sp2 and Sp3 Carbon structures open up a new perspective for future technological development in structural biomedical applications. The nanocrystalline particles produced by the detonation of carbon explosive materials (DANILENKO, 2004, GREINER

et al., 1988; OZAWA et al., 2007; CHANG et al., 2008) exhibit characteristic dimensions of 3-5 nm. Lubricants, galvanic coatings,

polymer nanoparticles, polishing systems, and niche applications recently used for electronics, emission devices, catalysts and combustion cells as nanocomposite membranes that lead protons

for the application of detonating nanodiamonds have been

proposed.

Figure

8: Left) Graphite (SP2 hybridization) and Right) Diamond (SP3 hybridization) Carbon

allotropic forms

Figure

9: Bucky-Diamond “onion” like cluster (left side): Nano-diamond core (lower

right side) with external graphitic shell (upper right side) and TEM of a

detonation nano-diamond atomic structure (right side)

However, preliminary clinical and biochemical investigations have shown

that these

detonating nano-diamonds are biocompatible and non-toxic, opening up new biomedical applications, taking into account both the variety

of surface chemical

light and the intrinsic mechanical characteristics.

The detonation of nano-diamonds, characterized by different

levels of purity and the presence

of unwanted functional groups/elements, can not be

directly

appropriate for biomedical applications in which chemical purity and chemical

uniformity of the surface

(LAI; BARNARD, 2011a; LAI; BARNARD, 2011b). After raw production, these materials

are subjected to purification procedures.

A simple method uses surface oxidation and different levels of purity and surface

properties can be obtained.

Oxidation carried out at elevated temperatures in an air/ozone atmosphere can lead to a purification of the carbon fraction not present

as diamond up to 95% by weight

(OSSWALD et al., 2006; SHENDEROVA

et

al., 2011).

Oxidation of nano-diamond surfaces other than elimination of unwanted functional compounds forms oxygen-containing groups (the blue dots in Figures 8 and 9) such as

anhydrides and carboxylic acids (SHENDEROVA et al., 2011) which are suitable for the polarization

of hydrogen

or polar with the appropriate species.

By purifying

air/ozone, we can work on

the very reactive and hydrophilic surface of the carboxylate, which is very suitable for biomedical applications (KRUEGER et al., 2008; KRUEGER et al.,

2006).

However, the toxicity of nano-diamonds remains controversial and is a real concern. In vitro and in vivo analyses

are required to evaluate characteristics such as mechanical and physiological behaviors in vivo (SCHRAND et al., 2009a; SCHRAND

et al., 2009b; ZHANG et al., 2011; YUAN et al., 2010).

Although biocompatibility and negative effect have also been described

in the literature on the use of nano silica particles, our published

investigations have shown that nano-composite and hybrid materials

made by combining amorphous silica nanoparticles have reached a high level of biocompatibility,

and micro-nanoparticles

and

p-HEMA.

These

hydrogel hybrid nanocomposites

have been tested for

water sorption, water swelling,

and isotonic saline

and for fibroblasts and osteoblasts as a cellular response with adhesion, distribution and morphology tests.

The presence of polymer-bound silica makes these biomaterials excellent only for pHEMA.

Good properties of osteoinduction were also observed

for the differentiation of stem cells from the dental pulp Marrelli

et al. (2015).

These self-assembled nanostructured composites were also tested as a peri-implanter scheme to match osteoblast growth factors

or stem cells for osteoblast differentiation (MARRELLI et al., 2015). This effect was mainly determined by micro-mechanical stress and the voltage generated

at the bone/implant interface.

These new hybrid materials have been shown to be able to stimulate biomechanical bone growth within the range of physiological strains

that allow for healthy growth to allow for complete early and organized

integration of the implant into the receiving bone. Creating ideal scaffolds

for bones is a growing argument for research. Such an ideal

framework should provide a rigid and elastic mesh to temporarily replace

damaged bone function while creating a bioactive

substrate for bone regeneration, integrating it fully (MONTHEARD et al., 1992; KABRA et al., 2017;

AVERSA et al., 2017a;

AVERSA et al., 2017b).

4. PREPARATION OF MATERIALS

The 3 nm detonation nanoparticles (Aldrich, ≥97%) with a specific surface area of 400 m2g-1 were used as bioactive filling agents. Nanodiamond hydrophilization was performed (SHENDEROVA et al., 2011; AVERSA et al., 2016a; AVERSA et al., 2016b; AVERSA et al., 2016c; AVERSA et al., 2016d). The surface

graft decomposition followed by functionality consists of the aggregate

dispersion of ~ 20 nm. Treatment

of hydrogen at high temperatures leading to nanoparticles Nanoparticles Nanoparticle nanoparticles of 2-4 nm was isolated by centrifugal isolation at> 10,000 rpm (SHENDEROVA

et al., 2011).

The nanodispersion was mixed with 2-hydroxyethyl methacrylate monomers (HEMA) (Sigma-Aldrich Chemicals Co., St. Louis,

MO, USA). The suspension of HEMA nanomaterials (Figure 10) was radically polymerized in the presence

of the azoisobutyronitrile

thermal initiator (AIBN, Fluka Milano, Italy).

4.1.

The nanocarbon content was prepared

at 2 and 5% by volume.

The degassed reactive suspension was first transferred to 2.0 mm thick flat molds and then

polymerized at 60 ° C

for 24 hours. Finally,

a cure at 90 ° C was obtained.

4.2.

Finite

Element Analysis (FEA)

Solid models of dental implants were generated using the Solidwork 2016 software.

The titanium implant

and the hybrid material replacing one part were molded. The FE model was obtained by importing

solid models into ANSYS rel. 9.0 FEM software (Ansys Inc. Houston)

using the IGES format. The volumes were linked

to tetrahedral elements,

resulting in a 3D FE model consisting of 31,240 elements and 35,841 nodes. The precision of the model

was verified by the convergence

test.

4.3.

Mechanical

characterization

The effect of elasticity measurement on the dried, swollen

and pendulous p-HEMA nanostructure was performed using a DTM METTLER-TOLEDO mechanical shear modulator (Zurich, Switzerland). The elastic

and viscous components of the shear modulus were measured with a constant

frequency in an isothermal state. The samples were vacuum dried at 60 ° C for 24 hours before testing. In the shear test mode,

discs of 10 mm diameter and 2 mm thick

discs are placed between three steel plates forming a symmetrical sandwich. An isothermal scan was performed

at 37 ° C in a nitrogen purged medium. Deformation control was set at 10 μm and a force limit of 0.9

N was applied at an oscillating frequency of 10 Hz (AVERSA et al., 2019).

The presence of the oxidized functional detonated nanodiamond in the monomer reaction

mixture favors the self-orientation of HEMA polar monomers

(Figure 10). The nanoparticles are in fact characterized by the presence of oxygen-containing groups leading

to a preferred

orientation and self-assembly of the HEMA hydroxyl

group monomers on the

nanoparticle sizing surface (left side of Figure

10).

Figure

10: Self-assembly of HEMA monomers in presence of functionalised Detonation Nano-diamond

(left side) and hypothesized Nanodiamonds pHEMA self assembled hybrid nanocomposite

(right side)

Nanosilica hybrid Nanocomposites have been described in a previous paper (Aversa

et al., 2016a) to show the self-assembled analog behavior that led to the formation

of nanostructured hybrid materials. Similarly, functional nanopowder that does not contain oxygen binding

atoms (red in Figure

10) and functional HEMA functional

groups can produce

monomer.

Figure

11: Camparison of mechanical shear properties on amorphous nanosilica and

crystalline nano-diamonds-pHEMA hybrid nano-composite

The polymerization of these silicates from HEMA / silica gel leads to the formation

of a nanostructured hybrid material

exhibiting specific

and specific properties, such as improved

mechanical stiffness and biocompatibility (AVERSA et al., 2016a;

PETRESCU et al., 2016a;

PETRESCU et al., 2016b; PETRESCU

et al., 2016c).

Applying this model of nanostructure formation to the nanodiamond / HEMA suspension polymerization, a similar improvement in mechanical properties and biocompatibility is expected.

However, improved mechanical properties are expected

to be more relevant due

to the high and high shear force

(Azo technology).

The stiffness of the synthetic diamond may be up to 15 times higher than that of silicon,

i.e. from the shear modulus

of about 450 GPa Vs about 30 GPa (Azo). By acting

as a filler or hybrid formation, nano-diamond detonation could generate the mechanical behavior of similar nanoparticle hybrids (AVERSA et al., 2016a), the behavior

of pure variation

according to the volume fraction

of hybrid diamond nanoparticles

in the material

could be assessed.

As

described by Aversa

et al. (2016a) aims at balancing

PHEMA hybrid nano- silicas

in physiological solutions. Water molecules that bind to polymeric hydrophilic groups induce a significant plasticization of the nanocomposite (in our case, a 16% by volume nanocomposite) that reduces the shear modulus of the dried initial samples from 8-9 GPa to

0.01- 1, 1 GPa 6, (AVERSA

et al., 2016d; AVERSA et al., 2019).

The compositional dependence of PHEMA impulse shear modulus is not described

by the classical Halpin-Tsai equation (HALPIN; KARDOS, 1976) valid for particle composites, but a linear dependence is observed.

These findings confirmed the hybrid character of pHEMA nano-silica

compounds.

On

the other hand, the same

stiffness can be achieved at a much lower volumetric loading

by using the nanodiamond, i.e., between 1 and 5% in the dry state.

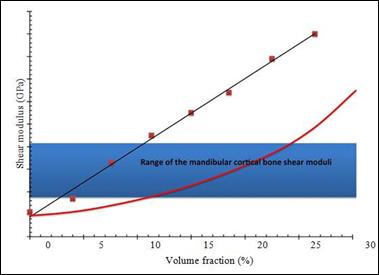

Figure 10 shows a schematic

of self-assembled PHEMA

nanodiamonds, while Figure 11 compares the shear modulus

that can be obtained using nanoparticulate amorphous particles and nano-diamond crystalline particles.

The

red points are the

2 and 5% nano-diamond shear modulus, measured in the shear mode using a dynamic

mechanical tester (AVERSA

et al., 2017b).

These preliminary tests have confirmed our estimated theoretical values for hybrid

configurations. Therefore, the adaptive properties of the bones can benefit

from the use of biomechanical and biomechanical materials (biomimetics).

"In vivo" Evaluation of bioactivity and osteoinduction

of implants

The in vivo study

aimed at assessing the bioactivity and osteoinductivity of the ceramic-polymer hybrid scaffold was presented by Aversa et al. (2016d). Unmodified titanium dental implants and siliconized nano-hybrid implants were tested for 2 months at the laboratory hamster femur. Micro-tomography was performed to evaluate

bone density and distribution

around the implant (AVERSA

et al., 2019).

The biomechanical and active osteoinductive characteristic of hybrid materials is summarized in Figure 12, in which microscopic microscopy and bone reconstruction and biomechanical analysis by finite

element analysis are compared

for the same active (left) and non-right biomechanical implants.

Active biomechanical coverage (100 microns) demonstrated that it is able to transfer

the physiological strains

necessary to avoid stress

protection and bone resorption in the vicinity

of the implant

neck (the green cross section of Figures 12a- 12c).

The explant implant (on the right side of Figure 12) shows a significant bone resorption process

in the same area (red circulating in Figures

12d-12f), which was correctly

predicted using the biofilm model (Figure 6b) for the final

bone implant figure 12f ).

FEM

analysis in the same area of the hybrid biomaterial coated implant predicted

a more physiological stress distribution due to the active biomechanical interface that stimulates

osteoblast growth (Figure 12c).

Commercial 2-hydroxyethyl methacrylate was purchased from Sigma-Aldrich Chemicals Co., (St. Louis, MO, USA). Smoke silicon dioxide (Aerosil

300 Degussa, Germany)

with an average

diameter of 7 nm and a specific

surface area of 300 m2 g-1 was used as a bioactive

filler. The initiator, α-α 'azoisobutyronitrile (AIBN), was purchased from Fluka (Milan, Italy). HEMA monomers with an increasing amount of chemical silica (4 to 30% by volume) were mixed. The resin was poured into 2 mm flat plates,

polymerized in an air circulation oven set at 60 °

C for 24 hours and

finally treated at 90 ° C for 1 hour.

Figure

12: Comparison of “in vivo” and Finite Element Biomechanical Analysis results

on a dental implant with and without the biomechanically and osteoinductive hybrid

coating

Planar samples were used for sorption and swelling experiments with aqueous isotonic

saline (0.15 M NaCl). The aqueous solution absorbed in the initially dried samples was determined at equilibrium by gravimetric measurements in a 0.1 mg Mettler Toledo balance sheet (Milano,

Italy). Advanced inflation left in the abnormal sorption

of sample II was monitored

by measuring the time of thickness

of the non- deposited residual glass core. The sorption and balance

swelling experiments were performed at 37 ° C (thermostatic water bath) until the monitoring of the constant weight

absorption monitoring (100 hours) was

monitored.

Solid dental implant models were created using the Solidwork 2007 software. Titanium implant and hybrid material replacing one part were molded. The FE model was obtained by importing

solid models into ANSYS rel. 9.0 FEM software

(Ansys Inc. Houston) using the IGES format.

The volumes were linked to tetrahedral elements, resulting in a 3D FE model consisting of 31,240

of 309 elements and 35,841 nodes. The

precision of the model was

verified by convergence tests.

Measurement of the elastic modulus by sampling the hybrid nanocomposite and the swollen

p-HEMA hybrid

was performed using a mechanical shear

METTLER-TOLEDO (DMA) (Zurich, Switzerland). The elastic

and viscous components of the shear modulus

were measured with a constant

frequency in an isothermal state. The samples were vacuum dried at 60 ° C for 24 hours before

testing. In shear mode, discs of 10 mm diameter

and 2 mm thick discs are placed between

three steel plates forming

a symmetrical sandwich.

An isothermal scan at 37 ° C was carried out in a nitrogen purged medium. The deformation control

was set at 10 μm and a force limit of 0.9 N was applied at an oscillating

frequency of 10

Hz.

The in vitro study aims to evaluate

the potential of nanomaterials to improve

the nanomaterials of nanomaterials Nanomaterials Nanomaterials (AVERSA et al., 2016b; SORRENTINO et al., 2007; SORRENTINO et al., 2009). Both the test body and the control

body were randomly assigned to four groups; each test group consisted of 9 implants,

while each control group consisted

of three fixed elements.

Insertion values ranging between

43.4 and 44.5 and between

44.2 and 45.7 Ncm were recorded in the control and control

group.

In groups 1 through

4 and in groups 5 to 8, the implants

were removed after 1, 6, 12 and 24 hours. The values of the removal torque

were recorded

as described

above. The in vivo study aims at assessing

the bioactivity and osteoinductivity of the ceramic-polymer hybrid scaffold.

Dental prostheses Unmodified titanium and modified

and coated prostheses were implanted into the rabbit

femur and eliminated after two months.

The micro-calculus tomography was performed on the explanted

femur, and the bone density

and distribution on the implant was

evaluated.

Our

research aims at designing a completed

biomimetic dental implant to stimulate

normal OB growth

in adaptable mandibular bones. To achieve

this result, both a suitable biomimetic scheme material and an external

implant screw piece should

be designed.

The biomimetic feature of our hybrid materials has been investigated for both mechanical properties and swelling

properties. The physiological behavior of the bone material

to be imitated from the bioactive material

of the scaffold refers to the following

aspects:

Mechanical properties (dry and swollen) Bioactivity (in vivo implant)

The PhEMA nanocomposite hybrid components with a concentration of 4 to 30 percent silicon dioxide volume were mechanically mechanically mechanically tested isometric, operating in a nitrogen atmosphere at 10 Hz and 37 ° C predominantly viscous viscosity of all compositions. The measured shear modulus is shown in Figure 13. The measured shear modulus of PHEMA-Nanosilica composites does not follow

the classical Halpin-Tsai equation for particulate composites (the ascending

line shown in Figure 13).

A

linear dependence of the shear modulus

values on the progressive loading

of nano silicon was observed.

This unexpected behavior

indicates the hybrid nature of PHEMA nano-silica

composites.

Figure

13: Shear moduli of the hybrid nanocomposites at different nano silica filler loading.

The theoretical Halpin-Tsai curve is reported for comparison in the figure

To

determine the appropriate nanofiller / p-HEMA ratio of the appropriate potential hybrid nanocomposite, the requirements of the target properties

are: Similar to bone rigidity

during implantation.

Shear modulators comparable to those of cortical bone were measured dry for nano silicon fractions

ranging from 4 to 12%. A 5% volume fraction

was then chosen

for sample preparation and FEA simulations (AVERSA

et al., 2016b; AVERSA et al., 2016; AVERSA et al., 2016c; AVERSA et al., 2016d; AVERSA;

APICELLA, 2016).

Elastic modulating (traction test) ranging from 2-20 MPa (strain-curing effect) was measured

for the swollen

hybrid composite (5% by volume).

This value becomes

comparable to that of the tense periodontal ligament

under the same conditions as articular cartilage.

The 5% hybrid nano-composite swells dramatically in isotonic aqueous solution, raising 50% of its dry weight while reducing

the shear modulus

to 2-3 MPa (measured

in DMA at 10 Hz). Such a phenomenon is associated with plasticization of the water-induced polymer that reduces the transition temperature of the polymer

glass below the test temperature 311. The sorption behavior was investigated in a

0.15 M isotonic isotonic isotonic

solution maintained at 37 ° C by hybrids

of glass with

a volume

fraction of 5% both for the weight absorption of the

solution and for the swollen kinetics.

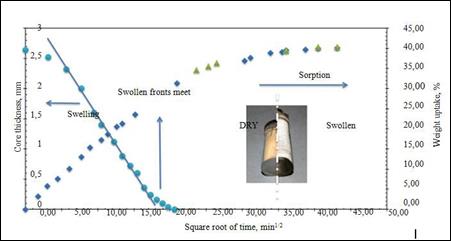

After exposure to the aqueous

solution, 2 mm thick coated PHEMA glass plates begin to swell with a clear face dividing the outer rubber portion and the untreated glass core.

The thickness of the correct glass progressively reduces

the front feed through

the sample. A measure

of the swollen kinetics,

which was reported in Figure

14 based on the square

root of time, is given by the rate of reduction

of the

glass core as a function

of time.

Figure

14: Swelling and sorption kinetics of a 5% by volume hybrid nanocomposite in 0.15M

NaCl water solution (isotonic)

The swollen face has initially advanced

at a constant

rate, according to the relaxed relaxed

relaxed mechanism of anomalies,

indicated as "case II sorption".

An initial

linear inflation rate is approximately 0.10 mm per hour. Since

the swelling

continues, however,

the diffuse resistance develops into the exfoliated outer skin, resulting

in diffusion-controlled swelling

of the remaining

glass core. When inflated fronts meet, the weight gain of the samples is about 27% but continues

to increase to a balance of 40%. This is due to complete balancing through the thickness of the sample.

At steady state, a 14.5% increase

in sample thickness

and a 50% increase in volume were measured.

These values were used to evaluate by simulating the analysis

of finite elements the dimensional changes that appear in the complex geometry of the modified

dental implant described in the following

paragraph.

The use of the active and biocompatible biomechanical interface has been "engineered" to reproduce

bone distribution compatible with the biomimetic. Intervals of physiological strains

and adaptive bone properties are reported.

There are superior surfaces (> 3000 m) (<50

m) that do not favor healthy bone growth.

The variable tension

of adaptive bone growth is bone resorption (<50 m), remodeling

(50- 1500 m), organized

growth (1500-3000 m), resorption (> 3000 m).

Biomimetic aspects are investigated using hybrid

osteoconductive nano- composite coupled with FEM modeling

of swelling and deformation of the hybrid

material. The proposed

solid CAD model of the new ceramic-polymer modified implant

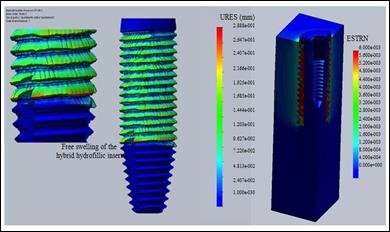

is shown in Figure 15.

Two biomechanical functions were considered during implant design: fixation of the implant

and stimulation of bone growth. A portion of the Ti screw

was replaced by the hybrid nano-composite that maintains the continuity of the outer yarns, while the interior, in which the remaining Ti core is conical through the threaded

tip, has a thickness of between

0.5 and 0.8 mm.

This thickening of the hybrid

ceramic-polymer hybrid nanocomposite produces, following inflation, a progressive volumetric increase

of

the peak. The scaffold

should play two biomechanical functions: one structural as part of the fixation device and one bioactive

as a stimulation stimulus of the bone. From a physiological point of view, stretching the periodontal ligament causes the new bone to fall into the toothbrush. Since the modulus

of

elasticity of the swollen

scaffold was comparable

to that of the periodontal ligament, the analysis of the finite

element confirmed that swelling

of the nanocomposite could act as a

biomechanical entry of bone

growth.

Figure

15: Thick elastic scaffold hybrid material mimicking periodontal ligament

functions in the Biomimetic implant: CAD solid model and a prototype for use in

“in vivo” tests of the new ceramic-polymeric modified Titanium implant

Figure 16 shows the results of a finite element analysis performed on the new implant simulating the swelling of the polymer-ceramic polymer insert in a physiological fluid: displacements up to 0.2 mm were calculated (after 8 hours depending

on the swelling velocity of 0.1 mm / h). This occurrence favors fixation and stabilization of the prosthetic device after implantation (the first biomechanical function).

Moreover, since remodeling is not triggered by the main stress

but by dynamic

loads (not static charges) on remodeling, a positive

growth stimulus is due to the presence of a deformed

hybrid at a physiological compression of 5-30 m; and stress

stress during bone healing and integration of the bone implant (second biomechanical function),

(AVERSA et al., 2016a;

AVERSA et al., 2019).

The blooming of the ceramic-polymer hybrid insert

then sets the implant into the bone and creates an active biomechanical interface for bone augmentation. Bone stress

was modulated by choosing a skeletal

swollen thickness

for healthy bone growth.

The in vivo tests performed using this new modified

oral implant confirmed

the improved ability

of these implants

to promote early osteointegration.

Figure

16: Displacements (URES) in mm and strains (ESTRN) of the hybrid

ceramic-polymeric insert undergoing physiological fluid free and constrained

swelling after implantation

This in vitro study aimed at assessing the possibility of improving

the primary stability of oral implants

through three-dimensional schemes consisting of a hybrid

polymeric material of

nanocomposite ceramic materials.

In

the test groups,

mean withdrawal rates increased progressively over time (diamond points) ranging from 61.2 after 1 hour to 86.2 Ncm after 24 hours, showing

how swelling of the scaffold improved the stability of the primary implant. In contrast,

in control groups (squares), the average values of the removal torque were between

43.7 and 44.9 Ncm.

Figure 17 compares the average

growth of the removal torque and the sorption/inflation kinetics.

Figure

17: Comparison between the kinetics of after implantation removal torque increases

and physiological fluid uptakes in modified implants undergoing swelling

The results of the Micro CT scan are shown in Figure 18. Thin hybrid implants

showed two main differences between osteoinductivity and bioactivity compared to unmodified implants:

•

avoiding bone resorption in the cortical

bone surrounding the implant neck

• improving osteoinduction

in the bone marrow

Immediate titanium implants showed significant bone resorption in the cortical bone.

This effect may be related to the biomechanical stimulation of incorrect cortical

bones outside the range of 50-3000 m. To avoid this undesirable effect due to a proper

mechanical stimulus induced by the interface of the hybrid bioactive hybrid material.

Furthermore, bone growth on the implant surface (the left implant in Figure 18) is due to the osteoinductivity of the hybrid skeleton material tested (AVERSA et al., 2016b; AVERSA et al.,

2016c; AVERSA et al., 2016d).

Figure

18: Biomechanicanics in adaptive morphology of the bone and osteoinduction

in the hybrid scaffolding materials

Biomaterials Today's science is a very interdisciplinary field that plays a central

role in the development of tissue engineering applications involving close collaboration between biologists, chemists, material engineers, physicists and clinicians who have researched in this area at a favorable level to new development systems. Regenerative medicine has developed

a lot and will guarantee many pat- to-bed applications (MONTHEARD et al., 1992; FILMON et al., 2002; DAVIS et al., 1991; KABRA et al., 1991;

APICELLA et al., 1997; PELUSO et al., 1997; CHOW et

al., 2010).

Biomimetic Ability (APICELLA; HOPFENBERG, 1982; APICELLA et al., 2010; ;

APICELLA et al., 2011; APICELLA

et al., 2015; AVERSA et al., 2009; PERILLO

et al., 2010; PETRESCU

et al., 2015; SCHWARTZ-DABNEY; DECHOW, 2003; TÖYRÄSA et al., 2001; FROST, 1990; GRAMANZINI et al., 2016;

HOLLEY et al., 1970; NICOLAIS et al., 1984; AVERSA et al., 2016a).

The new hybrid nanoparticles are prepared

by polymerizing the hydroxy-ethyl- methacrylate monomers filled with detonating nanotubes (up to 5% by volume). This material

absorbs water and swells in aqueous physiological solutions (up to 40-45% by weight),

transforming it into glassy and rubbery conditions. Low levels of non- diamond loads

can improve

the mechanical properties of hybrid materials.

Hydromechanically compatible hybrid hydrogels can be used as scaffolding materials

to increase stress

adaptation mechanisms to

micro and macro

prostheses.

The introduction of active biomechanical interfaces will improve biomimetic implantation while reproducing the biomechanical functions of cartilage and ligaments (APICELLA; HOPFENBERG, 1982; APICELLA

et al., 2010; APICELLA et al., 2011; APICELLA

et al., 2015; AVERSA

et al., 2009; PERILLO

et al., 2015; SCHWARTZ-DABNEY; DECHOW, 2003, TÖYRÄSA et al.,

2001; FROST, 1990; GRAMANZINI et al., 2016; HOLLEY et al.,

1970; NICOLAIS et al., 1984).

The use of metallic microtrabecular prostheses (AVERSA et al., 2016c;

AVERSA et al., 2016d)

coated with ceramic-polymeric hybrid scaffolds (AVERSA et al., 2016d) was proposed to recreate macro and micro-distribution

of stresses

and

deformations in the bone.

The development of polymer hybrid nanocomposites has been proposed in recent studies

(AVERSA et al., 2016b; AVERSA et al., 2016c; AVERSA et al.,

2019). These hybrid materials can induce the mechanical and biological properties needed to

promote healthy local generations.

The innovative features of a biomimetic approach are that the prosthesis is now designed to replace

the joint, damaged by various

causes, but does not stimulate

tissue regeneration. Also, the average length of a prosthesis is about 10/15 years,

while the new "biomimetic

prosthesis" will

last longer, estimated at 20/25 years.

This is very important because the average life span has increased significantly, increasing the number

of orthopedic surgeries

and health and social care

costs.

A biomimetic/biomechanical approach has been developed

in the design of a new modified dental material with bioactive ceramic

hybrid material for biomechanical stimulation and potential

improvement of the mineralization and ossification of the scaffold.

A polymer (pHEMA) filled with silica nanoparticles (4-6% by volume) was chosen as biomimetic material.

This material swells (approximately 14% linear)

in the presence of an aqueous

physiological solution

(when in an aqueous biological environment), raising up to 50- 30% by weight of water (depending on the nano-silicon load) of glass and soft rigid and rubber.

The mechanical behavior of the proposed hybrid materials is comparable to that of the bone when vitreous and cartilage (ligaments) when it is rubber

after swelling.

The bio-imitative properties of this very osteoconductive biomaterial have been used to develop a new bio-dental implant. The new concept is driven by the consideration

that a bioactive

interface

between the

implanted bone and

the prosthetic device is generated

when the material is able to stimulate the implant surrounding the bone in the physiological range of the strain for healthy bone remodeling and organized growth (50-3000).

The use of mechanically-compatible hybrid hydrogels as scaffolding materials is expected to increase

prosthetic adaptation mechanisms that introduce active interfaces that improve the implant

biomimetic while reproducing the biomechanical functions of cartilage and ligaments. The adaptive properties of biomimetic biomaterials (compatible with biomechanics and bioactive) are combined

with new prostheses (AVERSA et al., 2016a;

AVERSA et al., 2016b; AVERSA et al., 2016c; AVERSA et al., 2016d).

5. CONCLUSIONS

It is necessary to develop new biomaterial technologies to produce

scaffolds and bone substitutes that could play a fundamental role in bone regeneration. Bone forms

must exhibit specific

intrinsic characteristics to function as a replacement of the actual bone,

respecting biological, mechanical and geometric constraints.

5.1.

These

features include:

·

Biological Requirements -

Computerized schemes should allow cell adhesion and homogeneous distribution,

growth of regenerative tissue, and ensure the passage of nutrients and chemical

signals. This achievement was achieved by controlling the scaffold porosity;

·

Mechanical requirements -

Schemes must maintain mechanical and hardness properties that allow

osteoblastic colonies to have physiologically and bio-actively controlled deformations.

This was done by correctly modifying the composition of the ceramic-polymer composition

(in our case, 10% by volume amorphous nano-silica).

The combination of clinical observation of traditional implantation behavior will be used to validate

the bio-fidelity of FEM models, while the comparison of in vitro simulated in vitro growth

of osteoblastic colonies

would allow us to explore many new ideas in the design, design, and fabrication of new structure nanostructured cellular

cells with increased functionality and

increased cellular interaction.

This proves to be particularly useful in the direct

design and manufacture of the complex skeletal scaffold.

The new type of biomimetic implants can find applications in the knee, ankle, hip, shoulder and

orthopedic column.

Another area of application of biomimetic schemes is surgical oncology to support and facilitate bone regeneration, resulting in massive

losses due to primitive

and metastatic tumor removal

interventions.

The prosthetic system could allow for better

functional recovery by promoting bone recreation to ensure good maintenance even if it will have an impact on the quality of life of the individual patient severely affected

by the oncological pathology underlying

it.

The biomimetic solution combining a metal support

structure (to guarantee

load resistance) an osteoinductive and biomechanically

active bone (which promotes bone regeneration) finds replication in all surgical treatment

areas involving bone removal

and requires regenerative stimulation of the resected

tissue. In fact, the concentrated bone marrow

contains growth factors and

mesenchymal stem cells that can specialize

in bone cells, cartilage cells, and tendons.

A biomimetic/biomechanical approach has been developed in the design of a new dental material

modified with hybrid ceramic hybrid material for biomechanical stimulation and potential mineralization and ossification of the scaffold.

Polymer (pHEMA) filled with nano silica particles

(4-6% by volume) were chosen as biomimetic material. This material

swells (approximately 14% linear) in the presence of an aqueous

physiological solution

(when in an aqueous biological environment), raising up to 50-30%

by weight of water (depending on the nano- silicon

load) of glass and

soft rigid and rubber.

The mechanical behavior of the proposed hybrid

materials is comparable to that of the bone when

it is glassy and cartilage (ligaments) when it is rubber

after swelling.

The bio-imitative properties of this very osteoconductive biomaterial have been used to

develop a new bioactive

dental implant.

The new concept is driven by the fact that the bioactive

interface of the scaffold between the implanted bone and the prosthetic device is generated

when the material is able to stimulate the implant surrounding the stem to reshape the healthy bone

and increase growth (50-3000).

The use of mechanically-compatible hybrid hydrogels as scaffolding materials is expected to increase

prosthetic adaptation mechanisms that introduce active interfaces that improve the implant

biomimetic while reproducing the biomechanical functions of cartilage and ligaments; (Adaptive properties of biomimetic biomaterials

biomechanically and bioactive compatible of biomass, combined with new prostheses).

6. ACKNOWLEDGEMENT

The Authors acknowledge Liquid Metals Technologies Inc, Ca USA that kindly

supplies the samples for

the characterization.

7. FUNDING INFORMATION

This research has been funded by Italian Ministry of University

and

Research project FIRB Future in Research 2008 project RBFR08T83J.

REFERENCES

ANNUNZIATA, M.;

AVERSA, R.; APICELLA, A.; ANNUNZIATA, A.; APICELLA, D.; BUONAIUTO, C.; GUIDA,